Optical/photonic systems integrate many electronic components and subsystems that can be sources of breakdowns and failures when they are poorly adapted to the conditions of use or poorly integrated.

Drawing on their skills and the technical means in their laboratory, PISEO experts can identify the root causes of system failures and propose solutions to improve their reliability.

There can be many causes of failure in electronic and electrical systems. Our know-how and technical means allow us to provide the following services:

? Visual observation of and reproduction of defects.

? Dismantling of products and visual analysis of electronic components and board design and manufacturing.

? Optical, electrical, thermal measurements.

? Analysis of construction and materials used.

? X-ray analysis, FTIR spectroscopy, SEM microscopy.

? Production of an independent analysis report presenting the probable causes of failure and recommendations for improvement.

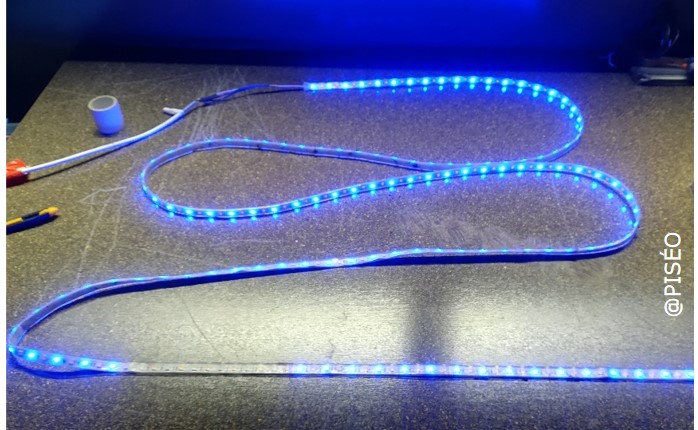

An installer of lighting fixtures turned to PISEO because he was confronted with operating failures on ribbons integrating colored light-emitting diodes (LEDs).

The failure noted was that certain segments of these ribbons no longer showed any illumination. After several fruitless searches, our client turned to PISEO’s experts to understand the cause of the problem and to find a solution with the manufacturer of the lighting equipment.

Our experts carried out an analysis of the entire system including LEDs, printed circuits, power supplies, digital multiplex (DMX) control, mechanical construction and heat sink. We verified the operating points of the LED components, and their electrical and thermal measurements. PISEO carried out visual observations with an image magnification device. Our experts were thus able to demonstrate that the malfunction observed was due to the failure of certain LEDs, itself caused by an electrical overvoltage external to the system.

This analysis revealed the probable causes of the failure. At the end of this work, we submitted an independent expert report to the customer.

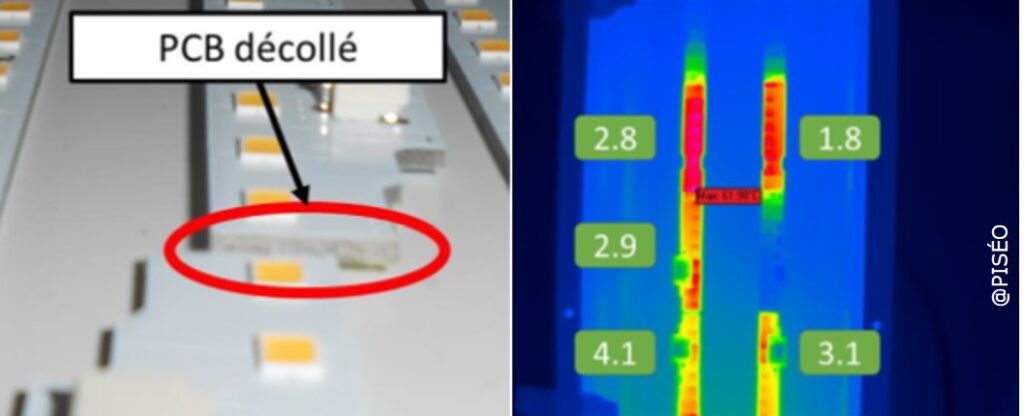

A distributor of LED lamps and lighting asked us to appraise a lighting device in which a certain number of LEDs were no longer lighting up.

During their analysis, the PISEO experts found that the design of the product did not correspond to the state of the art and involved risks.

Indeed, they were able to observe that by heating, the expansion of the LED printed circuit boards (PCBs) caused mechanical stress. This led to buckling and detachment of the PCBs.

The measurements carried out by thermal camera showed in particular that the chains of LEDs present where the PCB was peeling off also presented abnormally high temperatures, thus leading to the failure of certain LEDs. In this case, the design of the product could be called into question because the solutions implemented by the manufacturer did not take into account the phenomena of expansion of the PCBs during the operation of the product.

We know the lifetime of a single LED based on manufacturer data but this duration can vary depending on how it is integrated into a product. Some manufacturers may neglect this point and the consequences are often failures in installations.

Based on electrical and thermal measurements and extrapolation calculations, it appears that the temperatures in LED, PCB, resin, and plastic materials regularly generate failures such as those observed in the PISEO laboratory.

This was the case for a public lighting manufacturer who entrusted us with their thermal problem accompanied by a drop in flux over time.

Between the design and the production of the prototype, abnormally excessive temperatures had been noted by the customer.

After an in-depth study, the PISEO experts were able to identify that the main difference between the calculated configuration and the measured configuration was linked to the confinement of the heatsink caused by the presence of the power supply electronics support plate. This confinement limited air movement by convection and reduced the heat dissipation capacity of the cooler. The measurements taken show that the heatsink is about 20% less efficient than expected for this reason. By reconsidering the architecture ‘under the hood’, it should be possible to improve this thermal issue.

Description de ce bloc. Utilisez cet espace pour décrire votre bloc. N’importe quel texte fera l’affaire. Description de ce bloc. Vous pouvez utiliser cet espace pour décrire votre bloc.

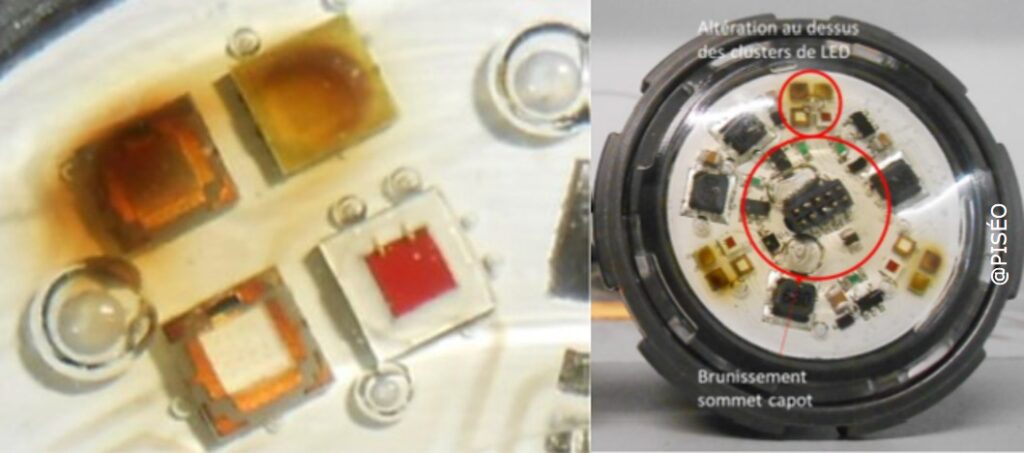

A swimming pool lighting device manufacturer was confronted with a phenomenon of browning of the silicone coating the LEDs, which ensure the sealing of its products. After consulting the LED manufacturer, who was unable to provide an answer, the product manufacturer turned to PISEO to find the cause of the failure.

During their analysis and in particular the disassembly of several products, the PISEO experts found that the silicone was not always correctly cross-linked and hardened and that it included a seal containing sulphur. However, non-crosslinked silicone exposed to optical radiation and in the presence of sulphur loses its transparency and changes color after a certain time. Thanks to their expertise in materials, optics and design of optronic systems, PISEO’s experts succeeded in identifying the cause of the failure. Our customer was thus able to improve his product and obtain a very significant commercial success internationally.

Binocular

Photometric and radiometric test benches

Fast oscilloscopes – Multimeters

Thermal camera and thermocouples

X-ray test bench – Electron microscopes – FTIR spectroscopy

PISEO also has the know-how and measuring equipment to take measurements on your worksites and in your establishments. These include illuminance readings, luminance readings, unified glare readings (UGR), contrasts, and photobiological risk. These measurements are relevant to normative and regulatory requirements such as EN 12464-1, EN 13201, EN 62471 and NF X35-103.

In the context of a dispute or an acceptance report, a measurement report from an impartial, independent and accredited laboratory can be decisive.