At a time when biometric security is becoming a major issue – border control, secure access, military cybersecurity – PISÉO is asserting its role as a strategic technology partner for the defense industry.

A concrete demonstration of this is our collaboration with an industry leader in the development of a large, flexible fingerprint sensor based on organic technology. This new-generation sensor paves the way for critical applications such as multi-fingerprint identity control in sensitive environments, and enhanced authentication on mobile devices.

For this sensor to live up to all its promises, it was necessary to take up a challenge that went far beyond simple lighting: to design a custom optical system adapted to particularly severe mechanical and electronic constraints. PISÉO was chosen to solve this demanding equation.

Unlike conventional sensors, this device had to operate in a confined space, without a frontal light source, while ensuring a sharp, homogeneous image, whatever the conditions.

The project presented several major technical constraints:

- Large surface area to be illuminated: As the sensor is much larger than a standard fingerprint sensor, uniform illumination had to be guaranteed from the center to the edges, without shadow zones or excessive variations.

- Thickness and integration: The flexible sensor had to fit into a compact device. The illumination system could not use sources above the finger (no front LEDs), but had to illuminate from the side or in the background, in the same way as e-reader screens, which are backlit from the edge.

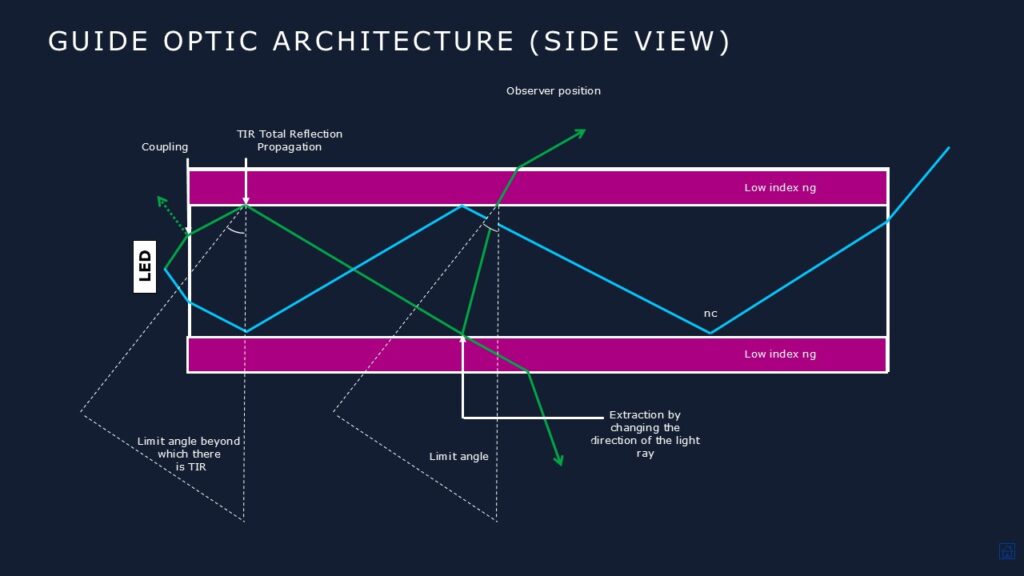

- Organic technology and optical stacking: The sensor is made up of innovative optical and electronic layers (organic polymers, thin films, etc.). A light guide had to be integrated to distribute the LED light under the footprint. The guide, in direct contact with other layers with no air space, radically altered light propagation and extraction. In addition, an angular filter was added above the sensor to allow only near-perpendicular light rays to pass through – a prerequisite for obtaining a clear image of the impression.

- Demanding operating conditions: The system had to operate in a variety of environments (e.g. variable ambient light) while maintaining high contrast between the ridges and valleys of the print. Stray light and unwanted reflections also had to be prevented from blurring the image.

Faced with such complexity, an empirical approach would have been time-consuming and uncertain. What was needed was a detailed understanding of the optical phenomena involved, in order to arrive at a reliable, optimized solution. This is where PISÉO made the difference, mobilizing its expertise in optical design and advanced modeling to meet the technical requirement.

PISÉO’s approach was to break down the problem into optical sub-systems and optimize each of them, while ensuring their overall smooth operation.

The main elements of the illumination system were:

- Lateral LEDs: chosen for their angle of emission and lens-free efficiency. The coupling with the light guide was carefully adjusted to limit losses.

- Integrated light guide: featuring microstructures just a few microns in size, inspired by flat-screen backlighting. Objective: to distribute light uniformly and at a precise angle.

- Multi-layer angular filter: modeled to block rays that are too inclined, allowing only light reflected directly from the ridges of the footprint to pass through.

3D modeling of the complete system: One of PISÉO’s strengths in this project was to use advanced optical simulation tools to create a digital twin of the biometric sensor. Each element – LED, light guide with its micro-structures, angular filter, and even the finger – was modeled to predict the system’s behavior. This approach made it possible to virtually test numerous configurations and identify optimal solutions even before physical prototypes were produced.

During this mission, PISÉO carried out several design iterations in close collaboration with the customer. Simulations were used to highlight the system’s key optical phenomena, enabling both teams to make informed technical decisions.

This approach enabled us to :

- Rapidly test numerous configurations.

- Predict optical performance before manufacturing.

- Reduce technical uncertainties and the need for prototypes.

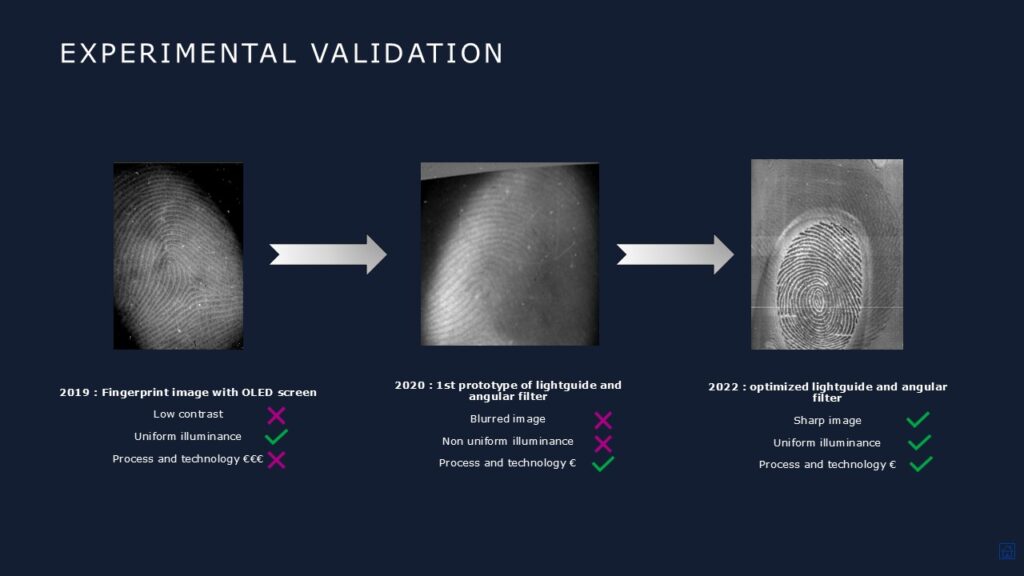

For example, the first version of the guide provided good uniformity, but the light cone was too wide. By fine-tuning the microstructures, PISÉO has refocused the light emission, increasing the proportion of truly useful light.

Simulations also revealed the impact of the material surrounding the guide (absence of free air, polymer layers), highlighting unexpected optical losses. PISÉO then recommended mechanical and optical adjustments to correct this.

The angular filter, difficult to grasp intuitively, was also modeled in detail. The results explained certain defects observed on the first prototypes (image edge blur), enabling them to be quickly corrected.

Throughout the process, the customer benefited from complete transparency on the optical phenomena involved in his system, such as the operation of the light guide, the impact of the angular filter and the importance of the choice of materials. The results of the simulations carried out by PISÉO made it possible to explain precisely the observations made by the customer during its own development tests. This in-depth understanding facilitated design optimization and reinforced the customer’s confidence in the product’s final performance.

Modeling a human finger involves more than simply reproducing a 2D pattern: its complex topography (ridges and valleys) and optical properties (scattering through skin layers) must also be taken into account. To this end, PISÉO conducted a photometric measurement campaign, using an optical goniometer to analyze light reflection on real fingers.

The data collected revealed a dual response: a reflection due to the skin’s natural moisture, and a wider diffusion. These characteristics were translated into BRDF (Bidirectional Reflectance Distribution Function) and integrated into the optical model.

The result: the simulation generated imprint images very close to reality. Compared with the physical images, they confirmed the accuracy of the model. Even the customer’s own image processing (by reference subtraction) was successfully simulated, revealing the details of the impression.

This advanced modeling, validated experimentally, strengthened the customer’s confidence and made development more reliable right from the start.

At the end of the project, the optimized illumination system developed by PISÉO was integrated into the customer’s fingerprint sensor. Tests on the final prototype confirmed the expected performance: the illumination is uniform, sufficient to distinguish every detail of the fingerprint, and the image obtained is sharp and contrasty across the entire sensor surface. Thanks to PISÉO’s advice, several crucial adjustments (choice of LEDs, design of the light guide, refinement of the angular filter, etc.) were made, leading to a fully operational device. The customer was thus able to refine his design and launch his product with confidence.

This new-generation sensor opens the way to concrete, mission-critical applications: multi-finger identification terminals in airports, enhanced security for mobile transactions, etc.

This project embodies PISÉO’s ability to transform demanding specifications into a ready-to-use industrial solution, even in the most constrained technological environments. For the Defense and Security industries, where every detail counts and reliability is non-negotiable, this expertise makes all the difference.

Thanks to its expertise in optical modeling, its rigorous approach to design and its close collaboration with customers, PISÉO doesn’t just solve problems: it provides a complete understanding of the system, accelerates development and secures technical choices.

In a world where technological superiority is a strategic issue, PISÉO transforms operational constraints into concrete solutions. For your optical detection systems, your authentication systems or your on-board optronic devices, PISÉO is a committed partner in the service of performance and security.