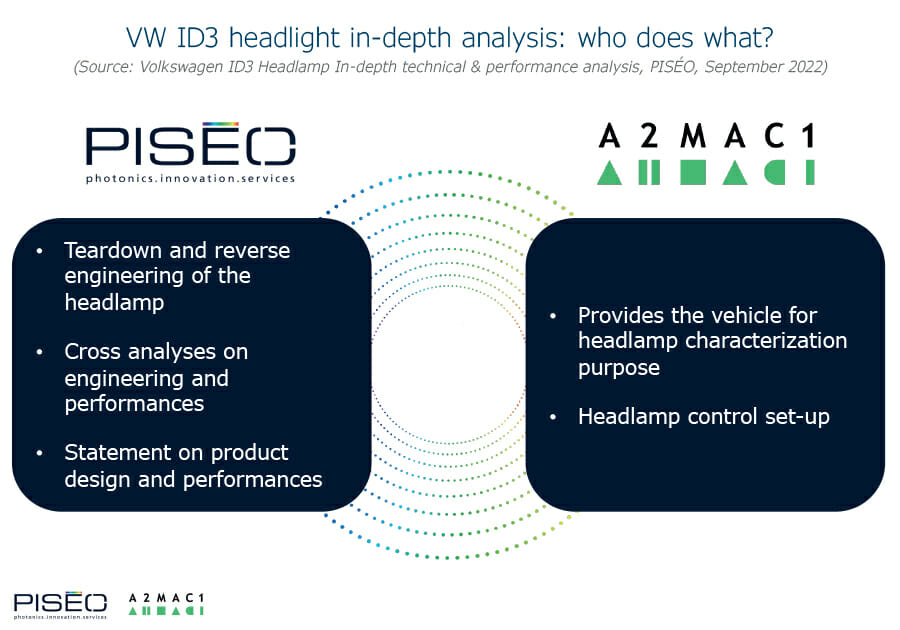

Objectives of the report based on PISÉO’s & A2MAC1’s collaboration

The integration of LED technologies has given automotive lighting manufacturers the opportunity for strong differentiation via new designs and functionalities. Automotive headlamps are subject to many technical and aesthetic considerations allowing multiple architectures and optical solutions. Therefore, OEMs and Tier1/2s are looking for accurate technical and performance insights of commercialized devices in order to consolidate their own product strategies.

PISÉO and A2MAC1 each provide unique complementary skills: PISÉO in LED-based system design and performance characterization, and A2MAC1 in automotive benchmarking. Given the complexity of a complete technical and performance analysis of a modern LED headlamp and A2MAC1’s long relationship with the automotive industry, the two companies collaborated to develop this report.

A2MAC1 provided access to the vehicle and set up the test, and PISÉO performed the technical and performance analysis of the headlamp.

Both companies are committed to providing the markets with the best possible benchmark data and insight into commercially available cutting-edge LED-based headlamps.

7990 €Add to cart

The analyses of both the architecture and the photometric performance confirm a high-quality product.

Sophisticated optical solutions have been designed and implemented to meet strong performance and integration requirements.

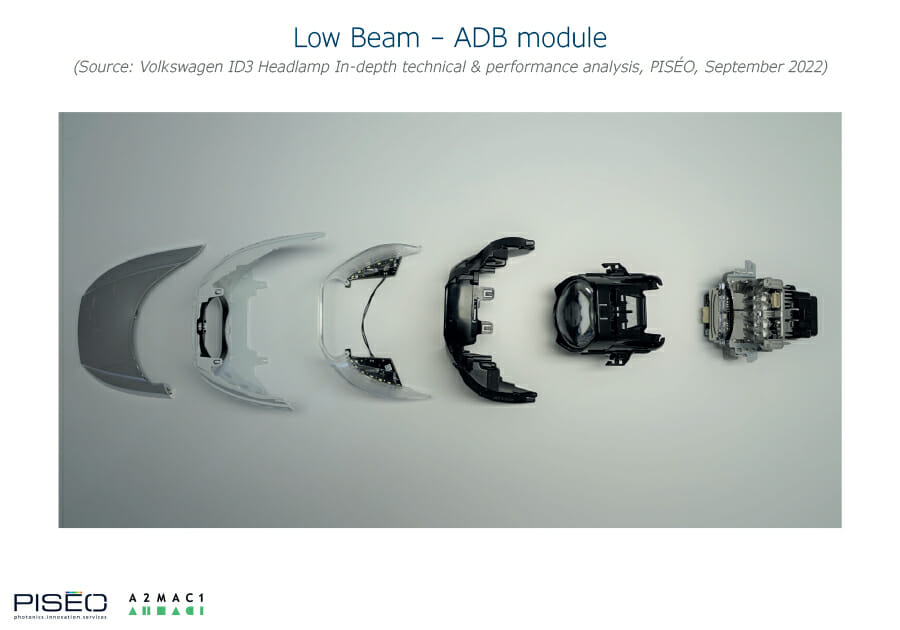

The ID3 headlamp embeds an ADB function whereby 1 to 11 LEDs are selected to extend the beam and cover more than the low beam. However, the resolution of the lit areas, being limited to 11 LEDs, appears low compared to other ADB headlamps installed on high-range vehicles, but it is a step up for this function.

The optical devices of the ADB function are nicely designed ancd well assembled, resulting in good beam quality.

Chromatic effects have been noted along the cut-off line of the low beam. This is due to the technical solution, which generates the cut-off line being unable to suppress the chromatic effect entirely.

Electronic solutions are not fully optimized. The LED choice is valuable, but the implementation on the boards shows a considerable variation and a lack of optimization with basic process constraints.

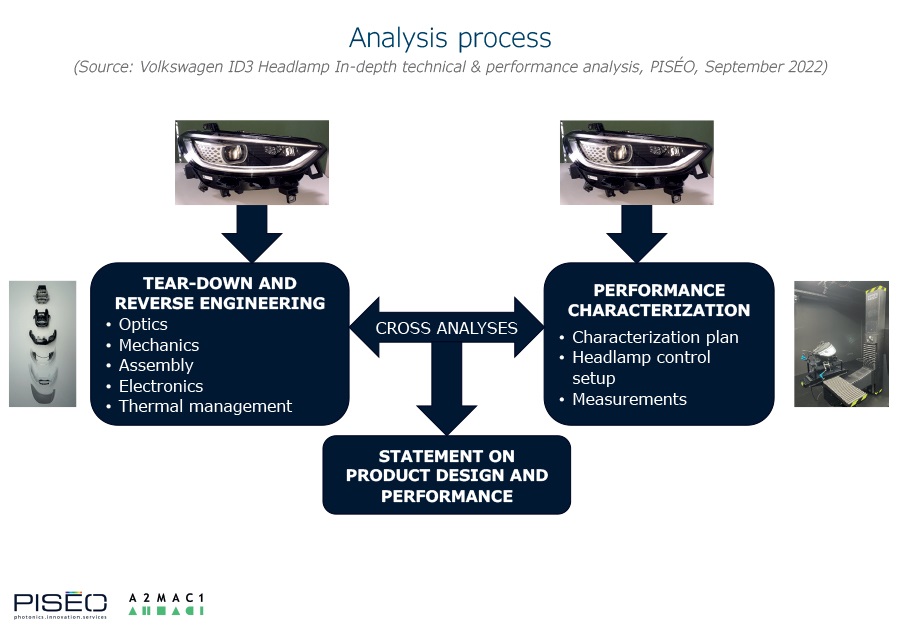

PISÉO’s analysis process, as applied to the ID3 headlamp, is based on two distinct phases: a teardown and reverse engineering phase (optics, mechanics, assembly, electronics, thermal management analysis), and a performance characterization phase (characterization plan, headlamp control setup, measurements). Two identical products are used, one for each process phase.

Based on the cross analyses of the outcomes of these two phases, PISÉO has provided a comprehensive statement on the design and performance of the headlamp

More reports will come soon which will allow fair product features and performances comparisons.