UVC optical radiation is part of the ultraviolet spectrum with wavelengths between 100 and 280 nanometers. It is very energetic and offers advantages for disinfection applications or industrial chemical processes such as PVC manufacturing. The systems used in these applications integrate UVC sources such as discharge lamps or LEDs.

PISÉO stands out for its expertise in designing custom LED-based UV-C sources adapted to the specific needs of its customers in various application areas. This expertise has proven particularly valuable during the COVID-19 epidemic, which generated a significant increase in the need for disinfection solutions. At the same time, the performance of UV-C LEDs has improved considerably in recent years, as shown in our UVC LED report.

Mercury-based UV tubes, historically used for disinfection applications, will be gradually withdrawn from the market by 2027. This deadline encourages users to review their strategies and look for alternative solutions. LED-based UVC sources now offer a viable and more environmentally friendly alternative. However, in order to reap all the benefits, the transition to this new technology requires specific know-how, which PISÉO has developed over the years.

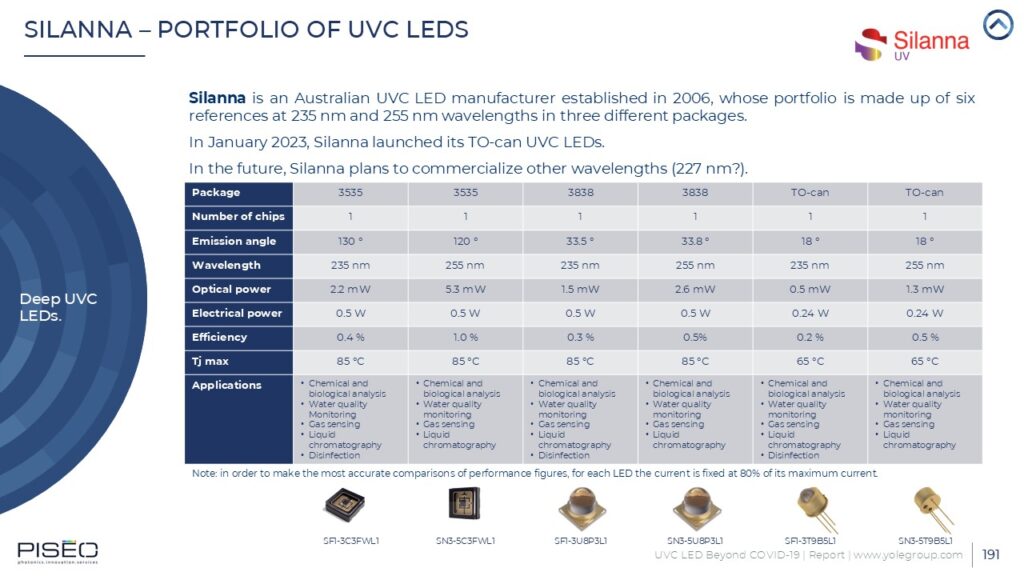

The design of an appropriate UVC LED source takes into account the optical, electrical, and dimensional characteristics of the components available on the market. As the COVID-19 epidemic has sparked a strong craze for disinfection devices, many manufacturers have developed a portfolio of more or less effective UVC LEDs. It is, therefore, essential to have a good knowledge of the broad range of these components in order to make informed choices. Performance tests in an optical laboratory, such as PISÉO’s, can be useful for discriminating between products and ensuring the correct characteristics.

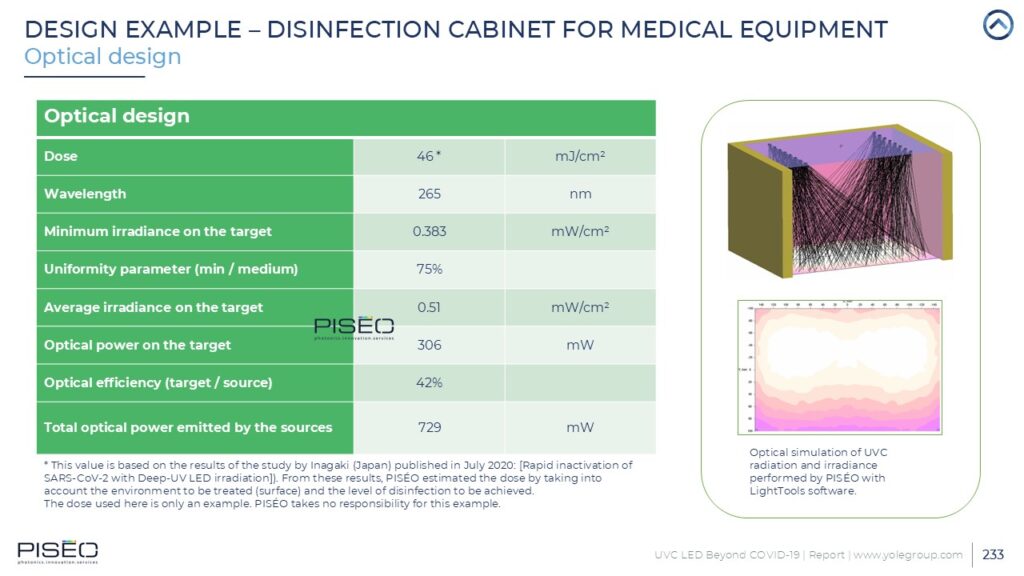

The specific application cases of UVC LED sources require a design approach that draws on a knowledge of physics, as well as biology and chemistry. For a disinfection source, for example, it is crucial to know the sensitivity of microorganisms to ultraviolet radiation in order to determine the dose and spectrum required to deactivate the DNA and RNA molecules of these microorganisms. This is the germicidal effect of the UVC source. Examples of doses for air disinfection are given in the International Commission on Illumination document CIE 155:2003.

Once the dose and spectrum have been determined, it is necessary to consider the environment in or on where the biological or chemical reaction will occur. Indeed, characteristics such as the geometry and materials of the exposed or fluidic surfaces must be considered during the design to guarantee the efficacy and durability of the systems developed.

Finally, LED system design know-how is required to ensure product performance and reliability. Once the component has been chosen, the integration of UVC LEDs requires in-depth work to provide the right level of energy illumination and maintain it over time, thanks to a precise optical design, suitable electronics, and efficient thermal management. The latter aspect is particularly crucial given the heat dissipation requirements of UVC LED components.

In conclusion, the transition to UV-C sources represents an opportunity to improve disinfection and environmental protection practices. Thanks to our expertise and commitment to innovation, PISÉO is positioned as a partner of choice for all companies wishing to adopt this cutting-edge technology. To learn more about our UVC source design services and discover how we can support you in your projects, do not hesitate to contact us.