Specialized in the development, production, and certification of high-tech products for endoscopic applications, this customer wished to benefit from PISÉO’s skills in developing tailor-made optical test bench.

Test benches are essential tools for measuring the optical performance of medical devices such as illumination systems used particularly in medical applications, more specifically surgery.

After devising a light projector integrated into an endoscope-type surgical robot, the customer wanted to measure the relative illumination delivered by this projector during its manufacture. PISÉO designed and produced a dedicated optical measurement bench for this purpose.

To meet the customer’s needs, PISÉO designed the measurement bench to manage the plurality of lighting profiles produced by the projector. The projector uses LED-type light sources that have various emission lobe angles, but also laser-type light sources whose beam is collimated. PISÉO therefore had to consider all the wavelengths between 400 nm and 850 nm emitted by these different light sources to design and build this test bench.

To meet the customer’s expectations, the PISÉO experts imagined an imaging system capable of reading the lighting profiles projected on a diffusing surface. The profiles measured in this way make it possible to verify in a simple and robust way, in production, that the light emission profiles of the projector comply with the characteristics expected of the projector once integrated. They then specified the architecture of the bench and its components including camera, lens, mechanical and electrical interfaces, then carried out the detailed design.

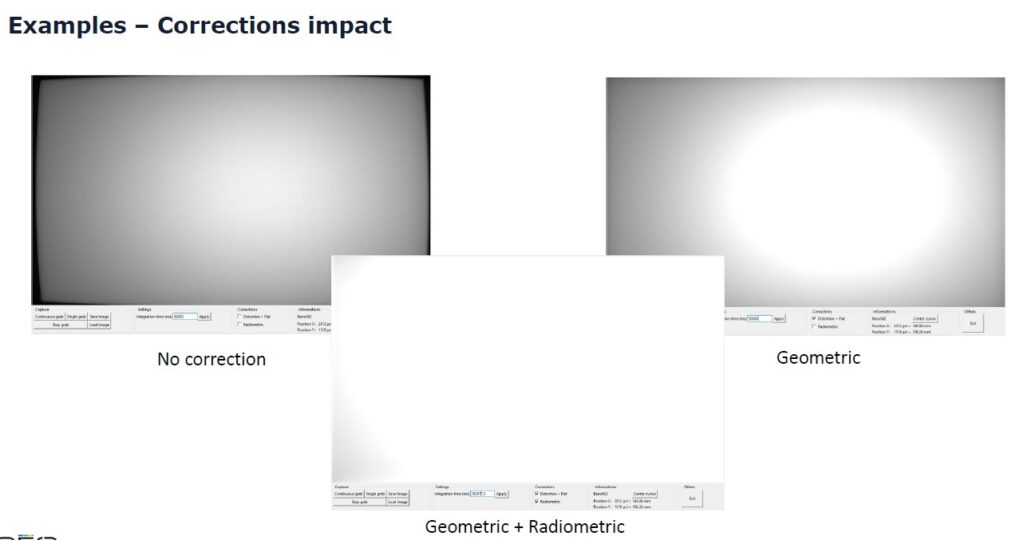

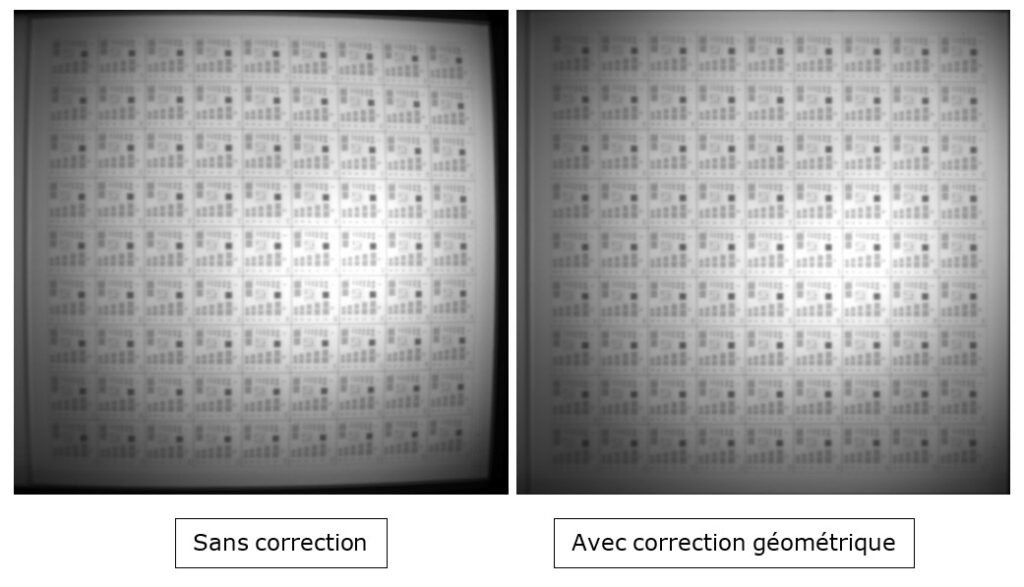

Because the lens of the camera used on this bench generates distortion and field curvature, it was necessary to first perform a geometric calibration to correct optical aberrations. For this, PISÉO used a checkerboard pattern, which made it possible to characterize the optical aberration of the system and to calculate the correction coefficients to be used by the algorithms for processing the captured images. The geometric calibration thus carried out makes it possible to draw up an illumination map meeting the precision required by the customer.

The second step was a radiometric calibration. This considered the diffusion characteristics of the frosted screen integrated into the measurement bench, the optical transmission of the objective, its vignetting, the sensitivity, as well as the spectral response of the camera sensor.

For this, measuring devices from the PISÉO laboratory calibrated under ISO 17025 accreditation (scope available on www.cofrac.fr), and more particularly the CAS140D spectroradiometer, were used to establish a reference illumination map.

The camera on the bench then acquired images of the frosted screen, with different integration times in order to process illumination profiles whose variations would the camera might not otherwise not be able to detect. These images were processed by an image processing algorithm developed by PISÉO experts. The algorithm is used to calculate the radiometric correction coefficients specific to the measurement bench, by comparing the calculated illumination map with the measured reference map.

This radiometric calibration has been validated for all wavelengths of the light spectrum used, including the visible and near infrared range, between 400 nm and 850 nm.

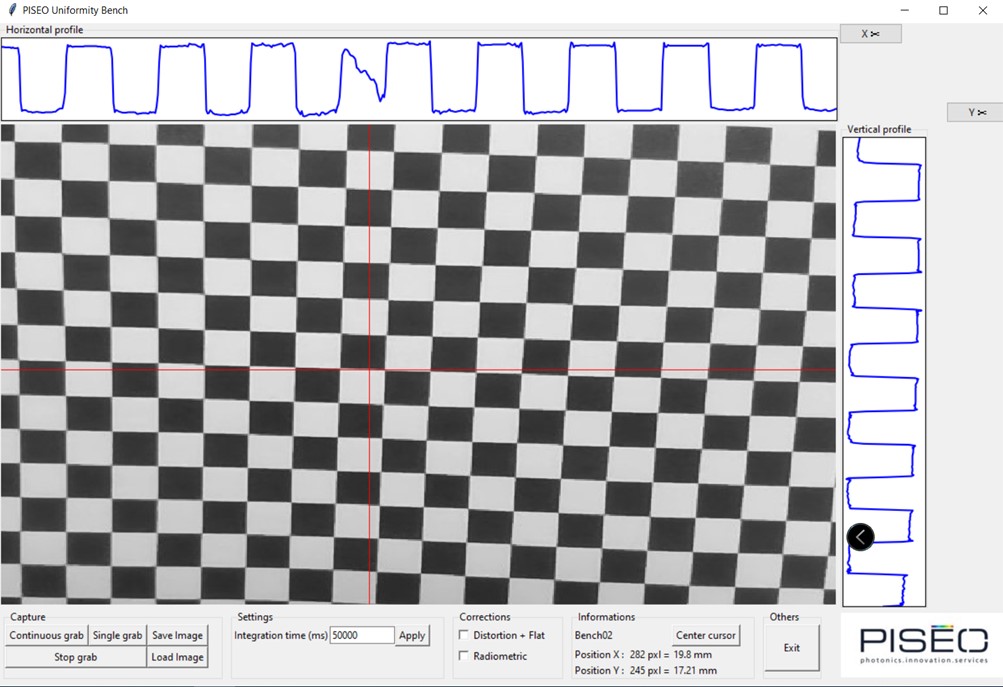

PISÉO also created measurement bench control software to allow adjustment of the alignment of the light projector on the frosted screen of the bench and adjustment of the camera exposure time. This software then makes it possible to visualize the image of illumination as well as the horizontal and vertical profiles, and to choose the point of the image from which one wants to study these profiles. It generates the illumination map from the images acquired according to a precise sequence and image processing adapted to the singularities of the light projector. It also manages the measurement bench by triggering an illumination measurement, by saving or loading an image. Finally, it gives the possibility of exporting an illumination map and/or the illumination profiles. PISÉO developed the human-machine interface (HMI), image processing, camera control and image management parts in Python.

The test bench had to be custom-designed to meet the specific needs of the client and to guarantee accurate and reliable results. The opto-mechanical design of the measuring bench made it possible to combine standard mechanical elements with custom-machined parts. This resulted in a compact, lightweight but robust design that could be moved by one person, be used on a workbench, and provide accurate, reproducible, and repeatable measurements over time. The cost price has been optimized from the design phase. The assembly and alignment of the bench were carried out in the PISÉO laboratory.

Once the measurement bench was assembled, PISÉO engineers carried out a series of tests to check its performance.

First, they did geometric and radiometric calibrations. The verifications focused on the calculations of the illumination profiles produced by a diffuse light source and by a collimated light source, which were compared with the profiles measured by devices in the PISÉO laboratory. The difference observed was less than the precision required by the customer, so the measuring bench was validated.

At the end of these tests, PISÉO recorded the geometric and radiometric calibrations in the measuring bench. The engineers set up management by serial number to manage the different copies of the measuring bench. They also compiled a user manual, a manufacturing file and a technical report gathering all the results of the tests carried out on the bench to allow the customer to understand the device’s performance.