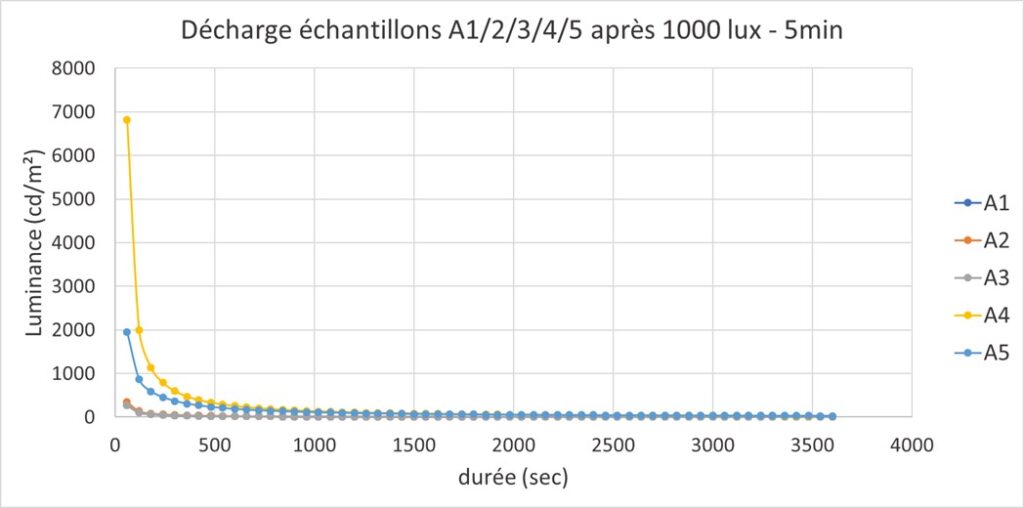

Luminescence is a type of photoluminescence – a phenomenon where a material absorbs energy under optical radiation and then emits part of that energy as visible light. When the energy supply stops, the material will continue to emit light at a certain level and for a certain time. This property, called remanence, depends on several parameters: dose received (energy x exposure time), spectral response of the material, and spectral distribution of the radiation received.

The applications of luminescence are wide and varied: watchmaking and luminous dials, signaling and security, marking and tracking, medical imaging, etc. These applications have various requirements, some of which must meet regulatory or normative requirements such as the ISO standard 17398. Also, it is important to be able to precisely characterize the afterglow of objects loaded with phosphorescent material.

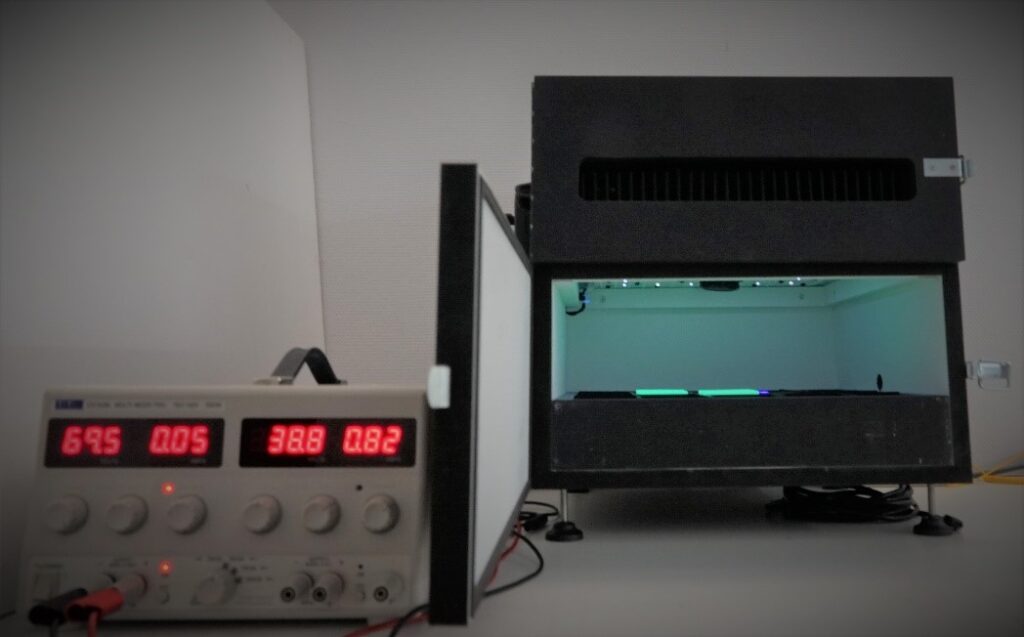

Drawing on our expertise in luminescence, optical metrology, and the design of LED lighting systems (ultraviolet, visible, infrared), PISÉO’s experts have designed and created a test bench to characterize the luminescence of samples of different types and sizes, whose varied uses provide for exposure to daylight. This test bench, which integrates a video-luminancemetry camera and a multi-spectral illuminator, is currently equipped in the PISÉO laboratory. It makes it possible for us to characterize customer samples in the form of a service. The bench can also be replicated or adapted for any customer who would like one.

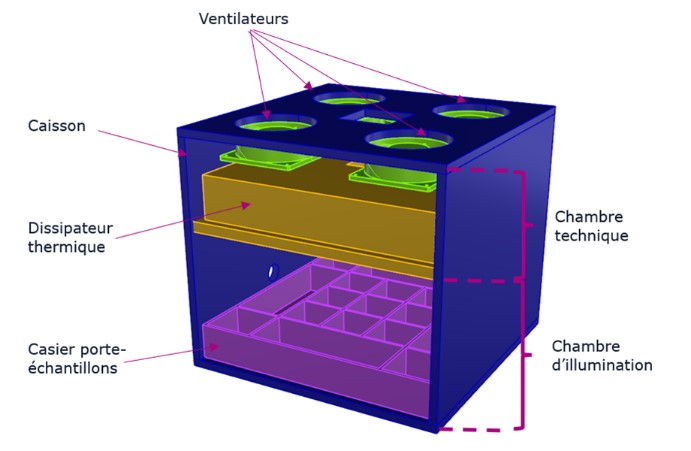

Before designing the bench, PISÉO’s experts specified the radiometric performances to be achieved on the samples to be tested, and defined the methods for recording the evolution of luminescence over time after being charged with energy. We also specified functionalities such as the control of light sources that make it possible to create the desired energy irradiance and light spectrum depending on the type of sample tested. We then evaluated the market offering of UV and visible LEDs and selected components likely to allow them (via appropriate combinations) to create radiation similar to that of the sun. Once all the requirements were defined and the concept imagined, we proceeded to size the multi-spectral LED illuminator through calculation and optical simulation.

The bench was then designed in detail. The mechanical part was entirely designed at PISÉO using SolidWorks CAD software. Furthermore, the LED illuminator integrated into the bench, which requires a significant amount of power per unit of surface area, was the subject of a thermal study. The results of this study led to the definition of the cooling components (radiator, fans). The electronic part was developed by a partner who has the means based on PISÉO’s specifications. The video-luminance camera, which makes it possible to record luminance levels and their uniformity over time, was calibrated equipment already available in the PISÉO laboratory. The image processing software is that of the camera.

Once the components and subassemblies were specified and supplied, the test bench was assembled and tested in the PISÉO laboratory. A detailed test plan was defined to verify performance and functionality against the initial objectives of the bench. Measurements of irradiance and spectral distribution were carried out using the Instrument Systems CAS 140D spectroradiometer, calibrated under ISO 17025 accreditation from the PISÉO laboratory. Finally, the repeatability and reproducibility tests carried out led to the validation of the test bench.