Imaging sensors are increasing in efficiency and require very precise characterization. A leader in state-of-the-art imaging sensor wanted to equip itself with a test bench to meet its new needs. Knowing PISÉO’s capabilities in the design, development, characterization and production of high-precision optical test benches, this leader entrusted their complex project to us.

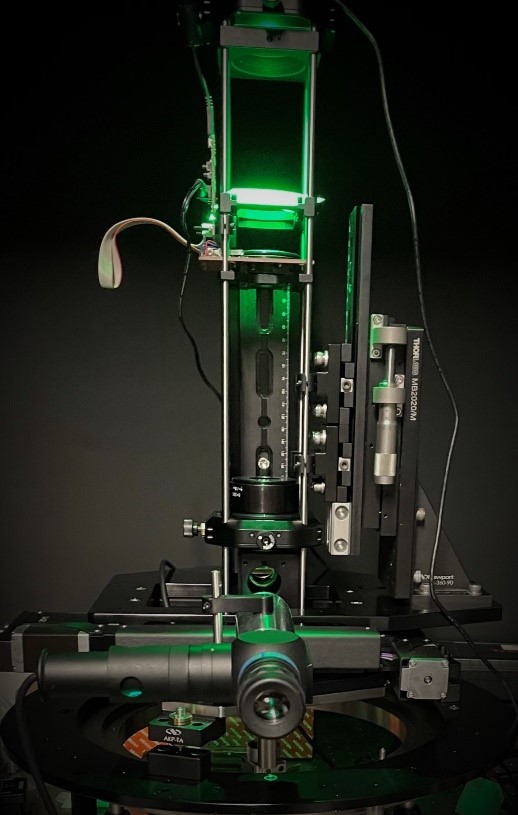

MTF (modulation transfer function) and QE (quantum efficiency) are key performance indicators of imaging sensors. Drawing on our experience in developing complex lighting and imaging systems, as well as our mastery of optical metrology, PISÉO’s experts have conceived innovative solutions that combine the measurement of these two parameters. The characterization bench thus integrates different LED and halogen light sources and optical devices, allowing precise control of uniformity and lighting levels. Everything is integrated into a high-precision mechanical architecture, itself interfaced with a wafer test bench installed in a clean room.

In order to enable measurement of the two parameters (MTF and QE) in the configurations desired by the customer and with the required quality, our engineers defined a suitable architecture. This specific architecture allows for great modularity of the different functions of the optical test bench while guaranteeing high measurement precision. To do this, we evaluated and chose equipment allowing movements below one micron.

The development of the characterization bench was structured in several phases. First, PISÉO’s engineers defined with the client the performance and usage requirements and the constraints to be considered. A feasibility phase made it possible to specify the architecture and components of the bench, which was then designed, assembled, and validated at PISÉO thanks to the optical, mechanical, electronic, and software engineering skills of our engineers.

Since the characterization bench integrates light sources, a photobiological risk assessment had to be carried out to ensure compliance of the device with regulations. This work was carried out by PISÉO through the expertise of our ISO 17025-accredited laboratory (scope available on www.cofrac.fr) for photobiological risk assessment. The results of the study made it possible to define solutions that would protect users of the bench.

The characterization bench was entirely assembled at the PISÉO optical laboratory. Numerous electro-optical tests were rigorously carried out to verify the reproducibility and repeatability (R&R) of the measurements. Uncertainty calculations were also carried out to assess the precision achieved by the measurements. The results of this work enabled the validation of the bench in the laboratory.

Because this characterization bench must be integrated into a wafer tester, PISÉO’s engineers ensured the assembly and validation of the bench in a clean room at the client’s site. We also trained their engineers in the use of the bench.

PISÉO’s customers trust our experts for the development and manufacture of complex, ultra-precise optical characterization benches.