With the widespread use of LEDs, human-machine interfaces (HMI) based on this technology combined with light guides are increasingly being adopted in various sectors, such as automotive, aeronautics, medical, and industry. Each of these sectors has specific requirements that these HMIs must meet. With its recognized expertise in this field, PISÉO was chosen by a leading client in the global sector of individual heating and hot water production systems for the optical design of a new series of HMIs.

The display quality of an HMI directly impacts the perceived quality of the product into which it is integrated. To meet the specific customer’s stringent requirements in line with its market positioning, PISÉO’s engineers translated its needs into photometry and colorimetry lenses. They specified the luminance, uniformity, contrast, and color points required for the customer’s HMIs.

Developing HMIs that integrate LED-based lighting functions requires very sophisticated optical engineering. These HMIs are often embedded in devices with complex shapes and must still meet important visual ergonomic objectives. In the case of this client, the shape of the pictograms and the limited size represented a real challenge. By mobilizing their extensive knowledge of optical technologies and systems, PISÉO’s optical engineers leveraged their creativity and simulation resources, such as LightTools software, to define an optimal technical solution.

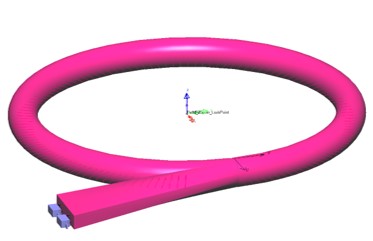

PISÉO’s optical engineers created several original and optimized light guides to meet the client’s needs. After considering the mechanical constraints of the system, they defined the very elaborate geometries that maximized the LED’s incoming flux in the optical guides and precisely controlled the light extraction. Thanks to these specific geometries, the client’s HMIs have no hot spots or light leaks. The light guide solutions developed by PISÉO also make strong contrasts and homogeneous color mixtures possible.

To be effective, light guides must be made from optical-grade plastic materials. For this project, PISÉO engineers used their materials database to offer different references. Optical simulation made it possible to evaluate these references with regard to various criteria, including performance and injection constraints.

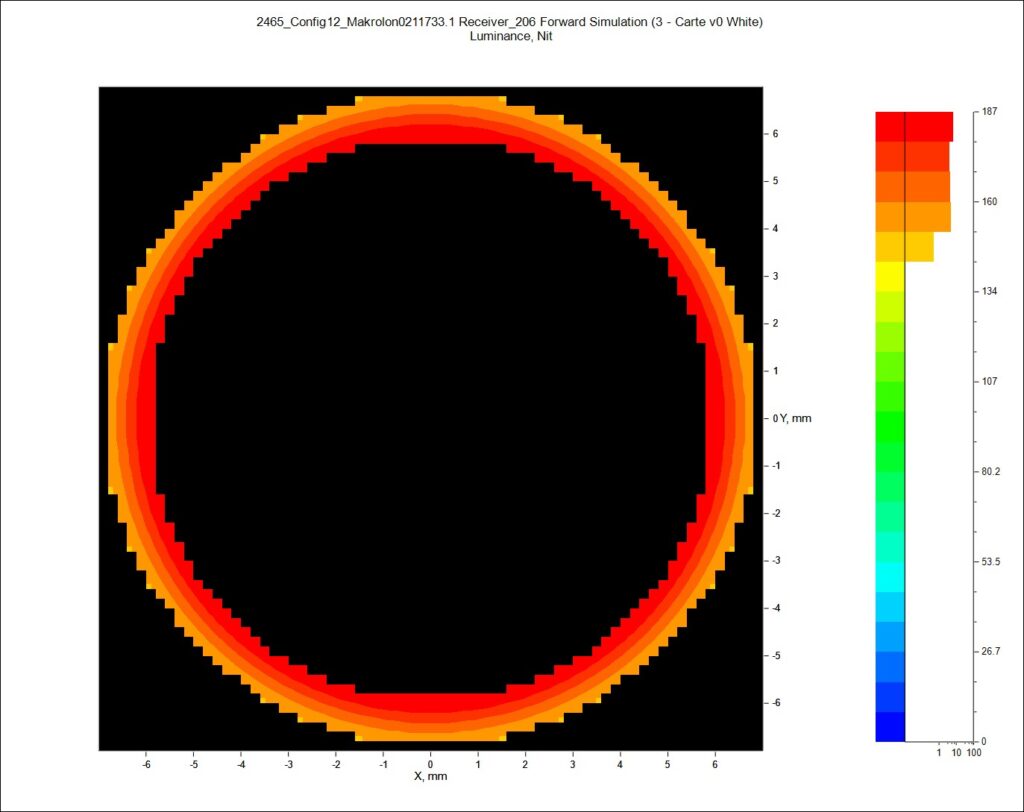

A prototype was produced by the client based on data provided by PISÉO. Its performance was characterized in our photometry laboratory to verify that the display quality corresponded to the simulations carried out during the design. Luminance measurements and mappings were carried out with a highly resolved video luminance meter. These tests made it possible to validate the work carried out by PISÉO’s optical engineers.

The findings of this project highlight the significant impact of optical engineering combined with cutting-edge simulation methods and rigorous photometry testing. Just like our satisfied client, you too can opt for excellence by calling on the unrivaled expertise of PISÉO engineers to design HMIs that offer exceptional display quality.