Over the past thirty years, endoscope technology for imaging has been developing and expanding its field of application. This technology is best known and used in the medical field for diagnosis and surgery. The flexible endoscope, made up of optical fibers , helps reach parts of the anatomy where access is sinuous (esophagus, stomach, colon, etc.). The rigid endoscope, in which the stem is equipped with lenses, allows for the exploration of an area in a rectilinear field and facilitates the detection and surgical treatment of tumors, infections, or malformations by minimizing the invasive nature of the intervention.

Multiple innovations have largely contributed to the improvement of the endoscope. The camera associated with the endoscope has, in particular, seen numerous developments. A true product of technology, it has benefited from improvements made to mobile phone cameras in terms of size and image quality. More compact, with better image definition and fields of view of up to 170°, endoscopic cameras are particularly appreciated by surgeons. They provide access to additional areas of the patient’s body with less trauma and faster recovery times.

In order to offer patients and the medical profession less invasive and more efficient solutions, manufacturers of medical equipment face real challenges. They must not only find innovative solutions in miniaturization and improvement of image quality but also ensure that these solutions are reliable and manufacturable .

It is in this context that PISÉO , a center of innovation and expertise specializing in the integration of optical-photonic technologies, was entrusted with a project to develop an optical system for rigid endoscopes. This included the study of a set of very small lenses adapted to the characteristics of a new sensor and the specific needs of one of its customers while taking into account integration and manufacturability constraints.

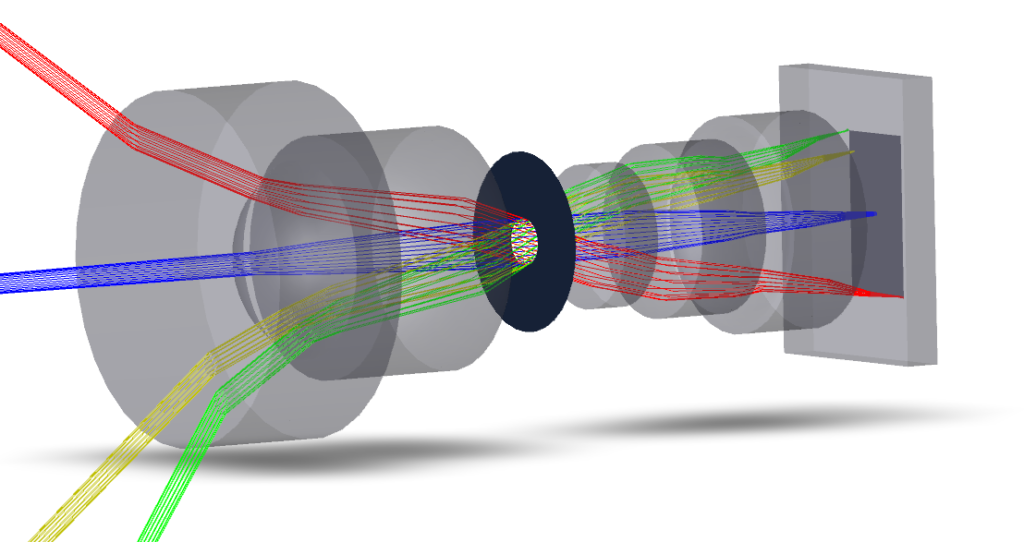

The dual objectives of miniaturization of the optical system and performance is a real challenge in the design of the optical system of an endoscope. In this project, the design phase involved taking into account specific technical constraints such as the diameter of the endoscope and the lenses, the size of the image, and the resolution of the sensor (number of pixels, frequency, contrast, spectral response, …), as well as working distance and depth of field.

Obtaining a quality image results as much from an optical design adapted to the system’s envelope as from the integration of a sensor, the characteristics of which must be perfectly known (angle of acceptance of the rays, resolution, etc.). The specifications required consideration of the integration of the optical part in two endoscope channels placed in parallel, with sensors arranged side-by-side or back-to-back using prism systems. It was, therefore, necessary to take into account not only the optical quality of the cameras but also the adaptation of the two channels and the size constraints of the final system. The optimization of the design and performance of the system was carried out through simulations using the optical design software ZEMAX.

The endoscope’s lighting system is stronger. It must be adapted to the area studied and as integrated as possible. The light must be white and bright, optimal for distinguishing the most subtle tissue lesions, for example. It may also be necessary for the system to produce wavelengths close to infrared to detect fluorescent markers, in particular facilitating the diagnosis of cancerous or pre-cancerous lesions. PISÉO ‘s expertise in the field of LED technology and its applications provided access to solutions that are particularly optimized in terms of the light spectrum and lighting levels.

In order to ensure that the design principles adopted are sufficiently robust, PISÉO assessed the impact of the integration conditions and the manufacturability of the lens. This work was carried out through in-depth discussions with the company charged with manufacturing the system. In particular, at the optical level, tolerancing work has been carried out. This work consisted of evaluating the performance degradation of the system linked to manufacturing defects or component placements.

Various parameters had to be considered: dimensions of the optical elements, optical surfaces, materials (index, constringent , homogeneity, etc.), supports, and optomechanical assembly. Thanks to its skills and tools, PISÉO ensured the performance of the entire system once it is assembled and mass-produced.

In this case study, PISÉO ‘s in-depth knowledge of optical systems led to the study of an innovative endoscope imaging system adapted to the customer’s specific needs. The company’s industrial expertise in all photonic technologies has made it possible to take into account integration and manufacturing constraints in order to ensure the performance of the optical system in medical equipment that can be industrialized. Thanks to PISÉO ‘s support, product launch times have been shortened, thus strengthening the customer’s competitive advantage.

PISÉO has a laboratory accredited ISO 17025 by COFRAC and benefits from a network of ISO 13485 certified partners for the development of medical systems.