Illumination, detection and visualization systems integrate optical components manufactured and treated from different (optics) materials. Indeed, these materials transmit, reflect, absorb, diffuse optical radiation in various ways and thus influence the performance of the systems that integrate them.

PISÉO’s experts use these materials to design innovative and high-performance optical systems. They therefore have a very large database of the optical characteristics of marketed materials such as polymethyl methacrylate (PMMA), polycarbonate (PC), glasses and anti-reflective coatings. The experts use these characteristics to perform simulations with tools such as LightTools or Zemax. They predict the performance achievable by optical systems once integrated including yields, illuminance, luminance, distortion, modulation transfer function (MTF) and colorimetry.

PISÉO is therefore an innovation platform and center of expertise in optics-photonics. To support its experts in optical design and its customers, PISÉO offers characterization services for materials for optics such as those described below:

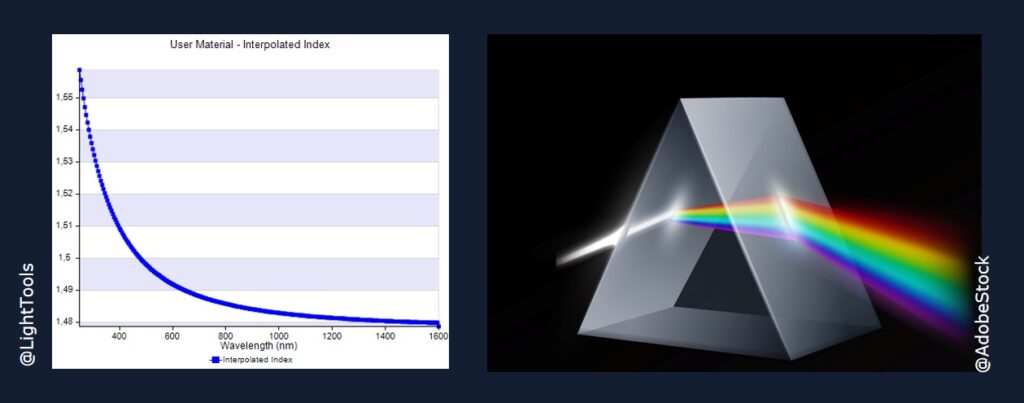

The refractive index varies with wavelength. Its precise measurement makes it possible to limit the risks of chromatic aberrations in an imaging system and to see colored fringes appear.

In a monochromatic system, the optical system will be optimized according to the material used. The simulated performances will be as close as possible to those measured.

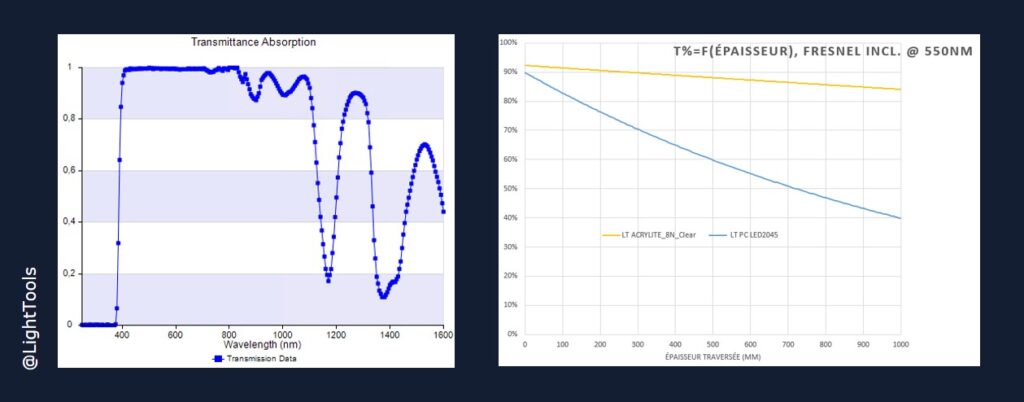

The transmittance of a material varies according to the wavelength and its thickness. PISÉO’s optical design experts can give precise photometric and radiometric performance according to the thicknesses of the materials envisaged and the sources used. Recommendations can be made on the use of different materials depending on the application and the industrial constraints of our customers.

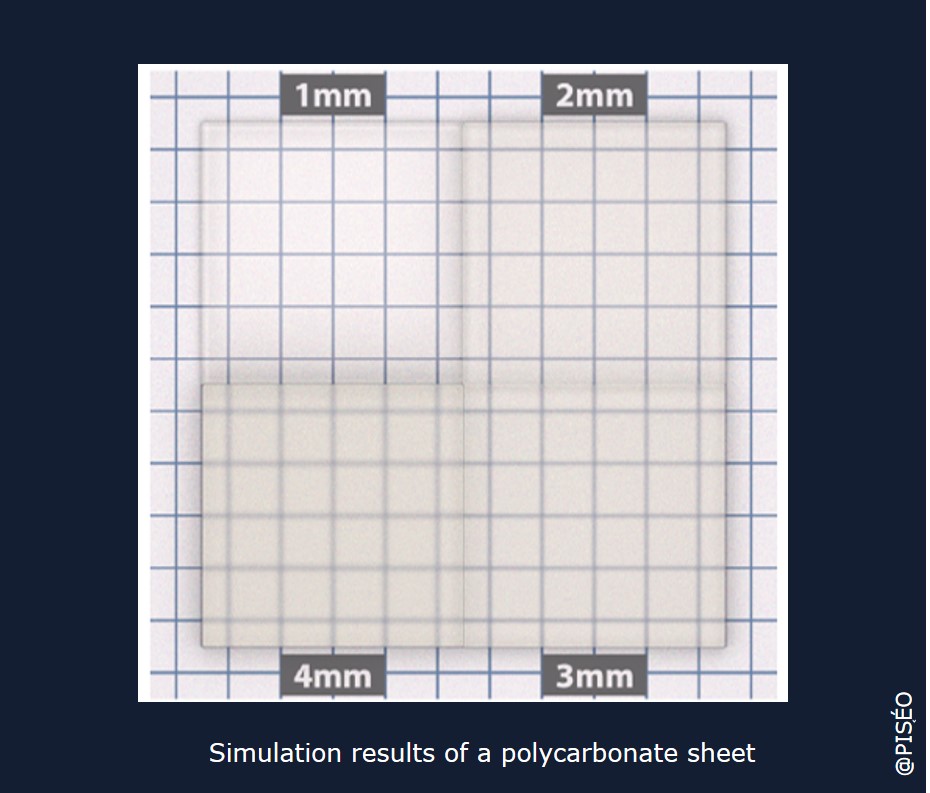

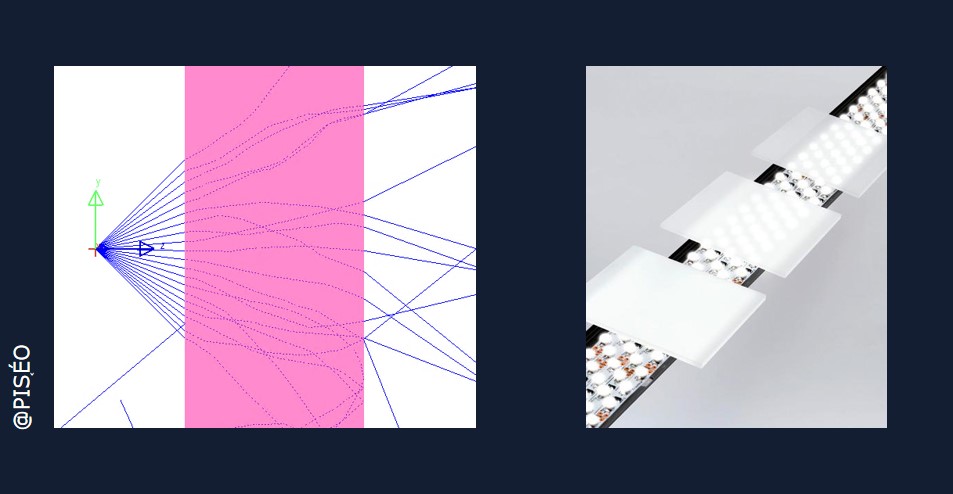

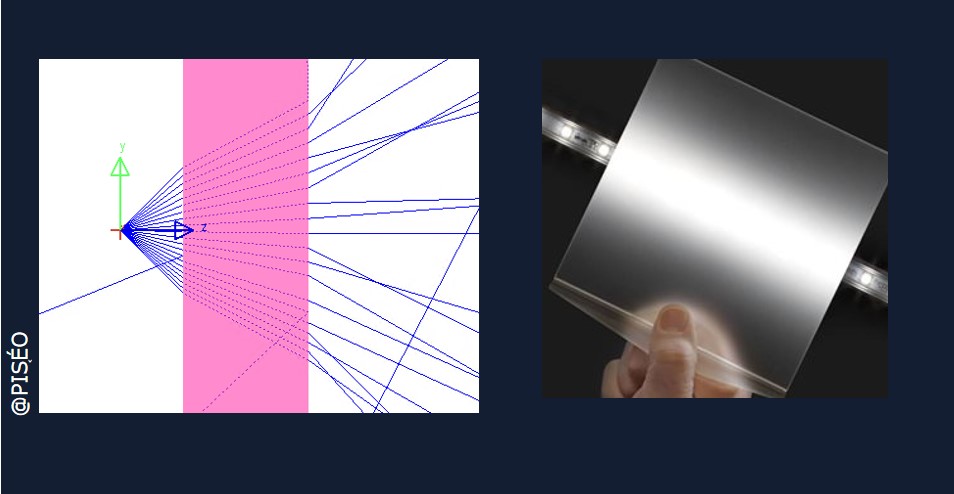

Diffusing materials are increasingly used to obtain light homogeneity and perfect uniformity, without hot spots. The diversity of materials makes the choice complicated depending on the application, such as lighting, automotive or visualization. PISÉO’s experts rely on precise measurements of materials from different manufacturers to calculate the uniformity and optical performance of the systems.

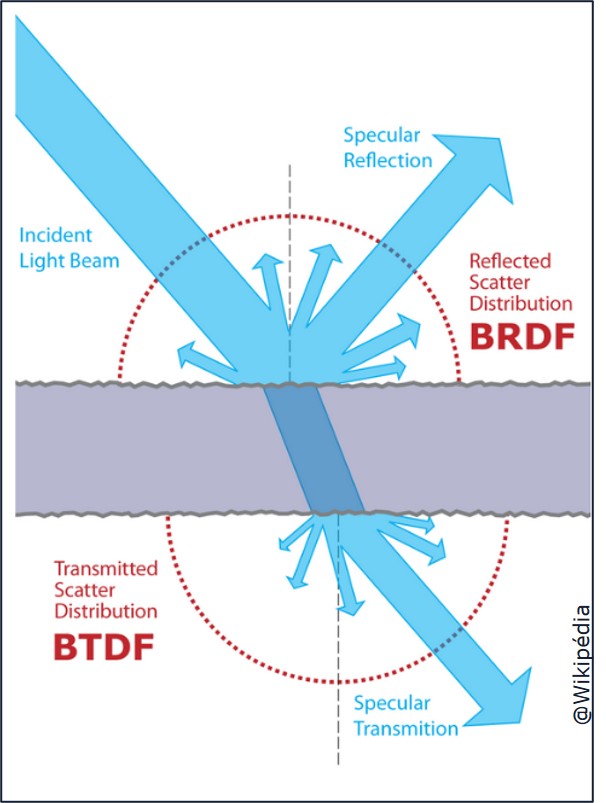

They import the bidirectional reflectance distribution function (BRDF) and bidirectional transmittance distribution function (BTDF) results into the LightTools or Zemax simulation software to size an optical system and obtain results close to industrial reality.

- Volume diffusion measurement for opaque or translucent materials:

Commercial references or samples can be measured through the Bidirectional Scattering Distribution Function (BSDF). This measurement also records how light is scattered in transmission via the BTDF and in reflection via the BRDF.

Experts charge the material with diffusing particles such as titanium dioxide. They can then provide the loading rate in a defined material such as PC or PMMA and adjust it according to the performance to be achieved.

- Measurement of surface diffusion for grained and textured materials :

Similar to volumetric diffusion, the BSDF of commercial references or custom samples can be measured. PISÉO has VDI 3400 and Mold-Tech injection mold texturing references for aluminum, PC, PMMA and silicone optics. We thus support our customers in the production of their textured molded part.