PISÉO now offers accelerated aging tests for polymer materials under controlled UV-C radiation. These tests enable manufacturers to anticipate the effects of UV-C radiation on material durability, even under demanding real-life conditions.

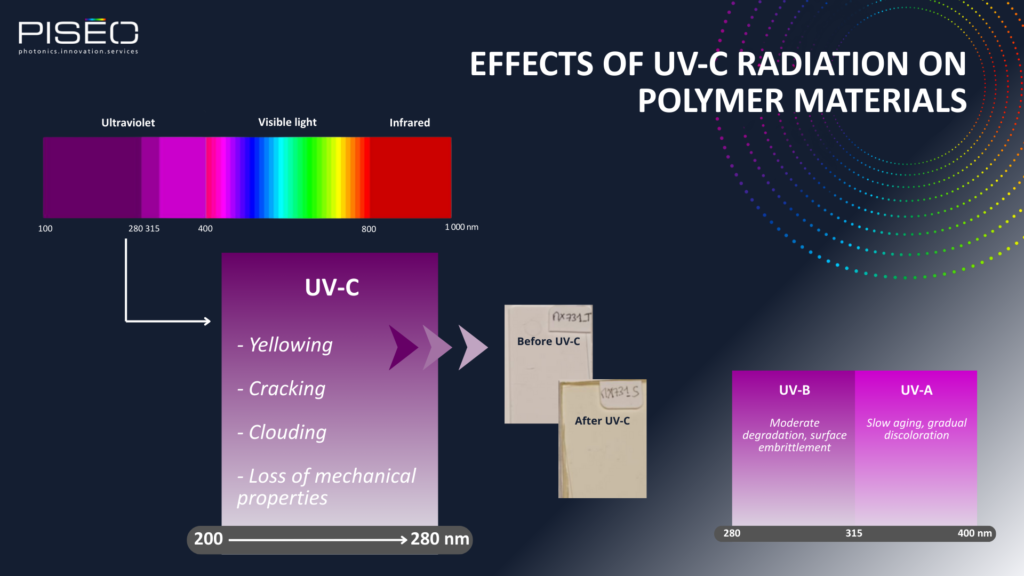

Type C ultraviolet radiation (UV-C) is a portion of the electromagnetic spectrum between 200 and 280 nanometers. Particularly energetic, it has a strong germicidal power: by altering the DNA of micro-organisms (bacteria, viruses, molds, etc.), it effectively eliminates them. This property explains its widespread use in non-contact disinfection processes, now deployed in many critical environments.

Traditionally emitted by low-pressure mercury lamps, UV-C radiation has undergone a technological revolution with the arrival of UV-C LEDs. These new sources offer unprecedented possibilities for integration into devices that are more compact, durable, energy-efficient and free of toxic substances. These developments open the way to numerous industrial applications, but also raise a new challenge: the resistance of polymer materials exposed to this artificial radiation.

The use of UV-C radiation now extends far beyond the medical field. The technology has been democratized in many industrial sectors:

- Healthcare and medical devices: disinfection of sensors, diagnostic boxes, surgical instruments or polymer contact surfaces.

- Automotive and transport: cabin sanitization via integrated UV-C modules, disinfection of interior components or air systems.

Aeronautics, defense, space: maintenance in aseptic environments, sterilization of equipment or exposed parts. - Food processing and pharmaceuticals: sterilization of production lines, packaging and containers.

- Electronics, sensors and home automation: air treatment devices, UV-C lamps integrated into domestic or industrial appliances.

- Cosmetics and packaging: purification of containers, primary packaging and care accessories.

In all these fields, the polymers used to manufacture hoods, lenses, interfaces or structural parts are subjected to recurrent exposure to UV-C radiation. Over time, this irradiation can alter the visual or functional properties of these materials.

Unlike UV-A (315-400 nm) and UV-B (280-315 nm), which originate from the sun and are well known for aging materials, UV-C does not occur naturally on Earth. Their much higher photon energy causes molecular degradation on the surface, directly affecting the optical and aesthetic performance of plastics. These alterations, even when they remain superficial, can degrade the perceived quality, safety of use or even regulatory compliance of the final product. The main effects observed when exposed to UV-C are:

- Yellowing or discoloration of transparent or tinted plastics, altering their visual appearance.

- Loss of transparency (opacification), problematic in optical or medical applications.

- Surface cracks or micro-deterioration, with a potential impact on hygiene or chemical resistance.

- Ageing varies from one polymer to another, and is difficult to anticipate without specific tests.

It is therefore essential to test the durability of polymer materials under UV-C to guarantee product robustness under real-life conditions.

PISÉO has developed an experimental test bench dedicated to the controlled simulation of UV-C aging. This device provides reliable, reproducible data on the resistance of polymers exposed to realistic doses of UV-C radiation. Main features of the test bench:

- Homogeneous irradiation provided by high-performance UV-C LEDs distributed on several sides within a reflective cavity.

- Precise irradiance control, adjustable from 1 to 100 W/m², depending on the desired test duration and target dose. Tests can be configured to simulate different exposures.

- Laboratory reproduction of the dose received according to a defined mission profile, enabling the test to be condensed to a controlled duration (e.g.: 10 exposures per day, 300 days per year, over 100 hours).

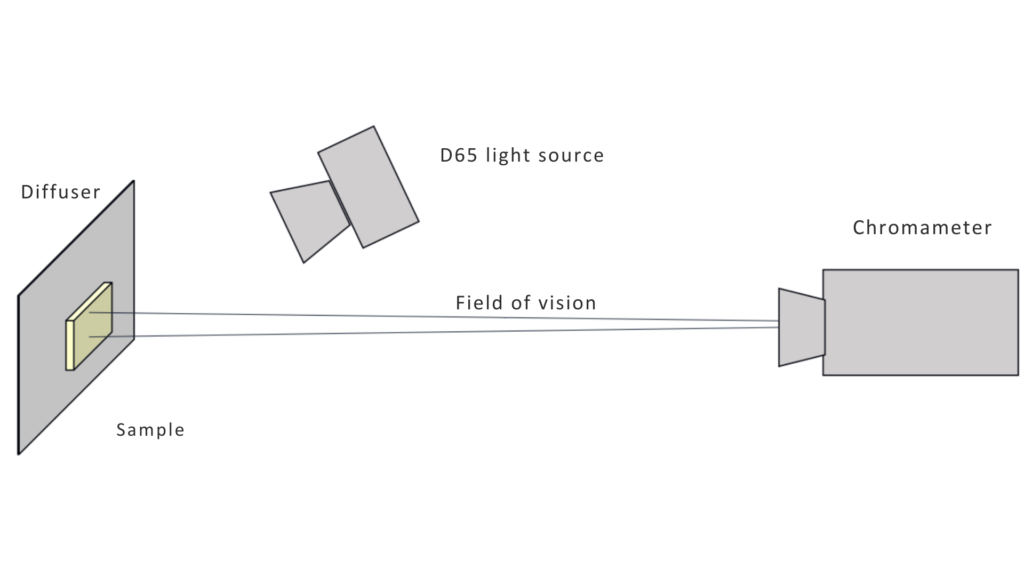

- Comparative analysis before/after irradiation, with unexposed control samples. Colorimetric measurement of optical drift (?E2000), a normative indicator of perceived variation (CIELAB space).

The PISÉO UV-C test rig and associated colorimetric measurement device are illustrated below.

All tests are carried out under controlled environmental conditions, ensuring high reliability and reproducibility of results.

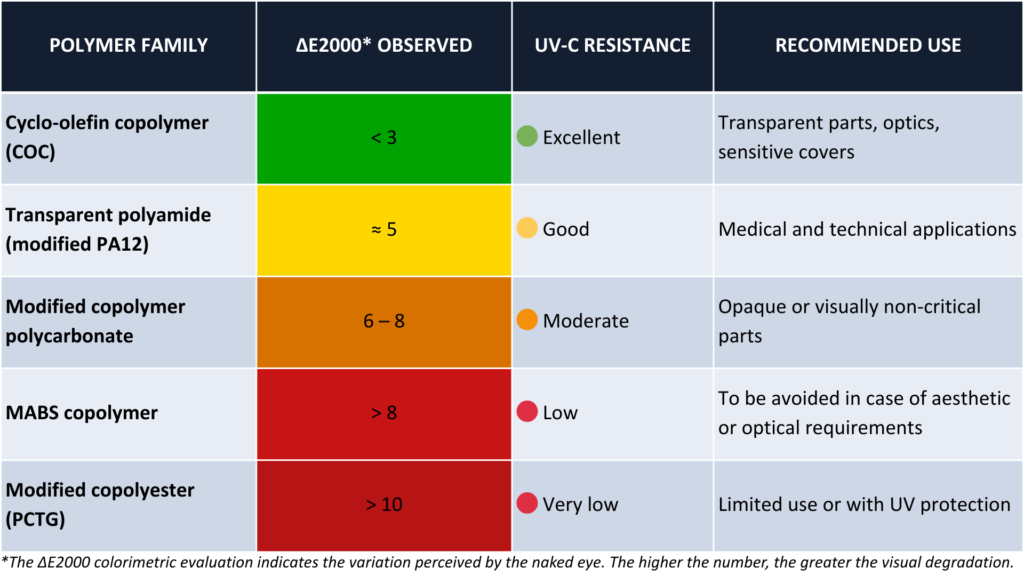

In its tests, PISÉO analyzed the resistance of several families of polymers used in medical, optical and industrial applications:

These results help manufacturers objectively guide their material choices and adapt them to real-world usage constraints, particularly when aesthetics or transparency are key criteria.

The UV-C aging tests offered by PISÉO represent real added value for all industrial players, enabling them to:

- Secure materials right from the design phase,

- Anticipate the effects of aging on aesthetics and functionality,

- Enhance product reliability and brand image,

- Justify performance in calls for tenders or approvals,

- Reduce costs linked to returns, after-sales service or late redesigns.

Thanks to its cutting-edge technical-scientific approach, its top-level characterization equipment and its skills in photometry, radiometry and applied optics, PISÉO has established itself as a benchmark player in the field of UV-C testing and materials qualification. Whether you’re planning to carry out laboratory tests, or to set up your own UV-C test bench, PISÉO can support you with turnkey, tailor-made solutions, perfectly adapted to your industrial constraints.

Are you developing a product to be exposed to UV-C? Would you like to validate your materials or compare different formulations? Are you planning to integrate a UV-C sterilization process into your equipment? Contact the experts at PISÉO today to benefit from high-quality, tailor-made support. You’ll have access to reliable, comparable data that can be used directly for your specific applications.