The phenomena of stray light (or flare) reduce the performance of optical imaging systems. It is necessary to identify their causes in order to reduce or even eliminate them by acting on the system’s physical parameters. PISÉO experts master these optical manifestations. Thanks to their knowledge of and expertise in optical simulation, they can help you understand and correct them.

Stray light refers to unwanted and unintended light in an optical system.

These light rays are generally due to surface scattering of optical and mechanical components. Stray light can also come from internal reflection between components, unwanted surfaces, or surrounding light.

They can appear in different ways in an image:

• A veil (veiling glare) resulting from the diffusion of light on the edges of the lenses or their surface.

• A ghost image: a sharp image seen by the sensor due to internal reflection on the surface of the lenses.

• A halo (flare): a more diffuse image closer to the light source.

• A starburst effect: linked to the shape of the diaphragm of an imaging system that diffracts light. This can be desired in photography for an artistic effect.

Stray light is a problem in optics because it can disturb the final image and reduce its quality. The image may be fuzzy or hazy, making it difficult to identify important details, particularly in applications such as microscopy or the spatial domain, for example.

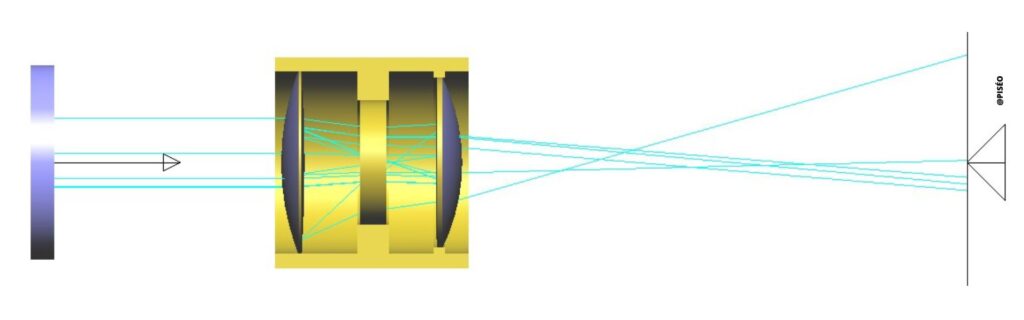

Imaging systems (projector, camera lens, etc.) are the most sensitive to stray light.

Indeed, these systems consist of several lenses, and multiple reflections on each face are liable to create undesirable artifacts. The optical subassemblies are integrated into a mechanical system that can reflect or diffuse light and create stray light.

To reduce stray light, it is essential to detect its presence and understand its causes.

Very often, the problem is first detected at the prototype stage and in tests carried out in the laboratory.

Indeed, stray light phenomena are generally not considered when designing an optical imaging system by means of simulations in sequential mode (using a Zemax, for example). Stray light issues require careful consideration of the energy aspect and non-sequential propagation. A tool like LightTools, mastered by PISÉO experts, is well suited for this.

To assess the risks of these phenomena during the design or in an existing system, we create complete models of the optical components and their environment (mechanical, light sources) in this tool, faithful to reality. These models also account for the optical properties of materials (refractive index of lenses) and surfaces (BSDF, surface deposits, roughness). We then use the model to perform simulations that highlight the effects of stray light and investigate their causes.

Once the causes are known, we can act on the system and propose improvements: geometry of optomechanical components, the addition of a baffle, anti-reflective coating, etc.

Julie Bonnetto is a specialist in the design of industrial optical systems. She holds an Engineering degree in Optics, Photonics, and Industrial Vision, and a Research Master’s in photonic micro- and nano-structuring obtained at Telecom Saint-Etienne. Before joining PISÉO, she held engineering positions in the optical design and development of LED lighting systems at SIGNIFY (ex Philips Lighting), then LED indicators and lights operating in harsh environments at MAFELEC. His responsibilities within PISÉO include high-stakes optical design studies in fields as different as lighting, automotive, health, telecoms, luxury watchmaking, and biometrics.