Used for display and signage applications, lighting solutions combining light guide and LED have become essential.

Their ability to emphasize lines and create signatures make them particularly attractive to designers and architects. Their low thickness and robustness allow them to be easily integrated into many systems.

In addition, their exceptional ability to guide light makes it possible to produce large luminous surfaces with excellent uniformity.

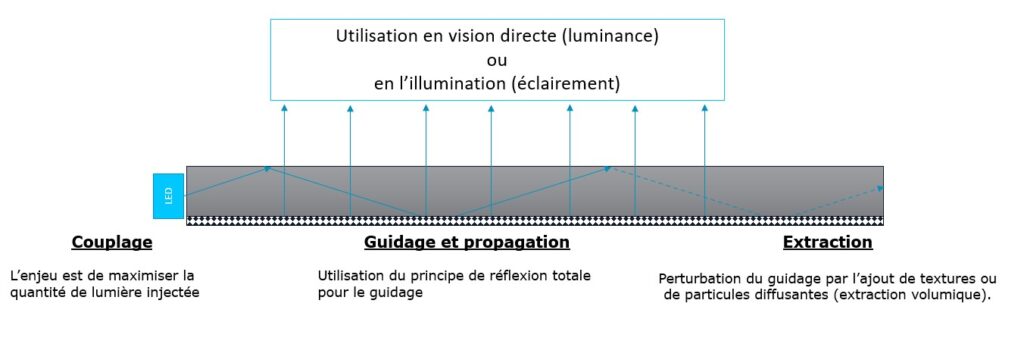

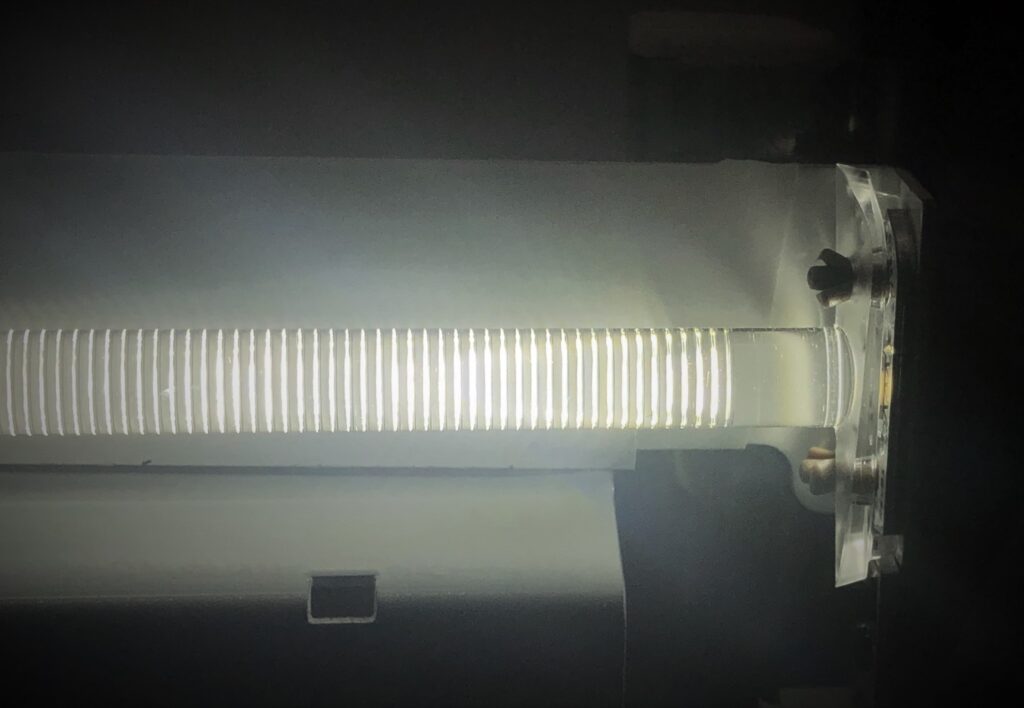

In these guides, LEDs are placed on the side and not under the surface to be illuminated. This arrangement makes it possible to reduce the number of LEDs while obtaining large, uniformly luminous surfaces in an extremely compact volume.

The reduction in the number of LEDs results in lower manufacturing costs for the manufacturer and a reduction in the system’s power consumption for the end customer. Indeed, to obtain a uniformity of 80% on the surface over such a small distance using LEDs placed under the surface, much more effort is needed than in the case of tangential lighting.

The low thickness of the guides (only a few millimeters) allows them to be easily integrated into many display and signage systems.

However, the design and production of light guides to achieve the desired luminance, uniformity, and illuminance require first-rate know-how and technical resources. Thanks to their vast industrial experience, their leading optical simulation tools, and their photometry laboratory, PISÉO experts can reliably and efficiently support you in developing all types of lighting systems based on light guides.

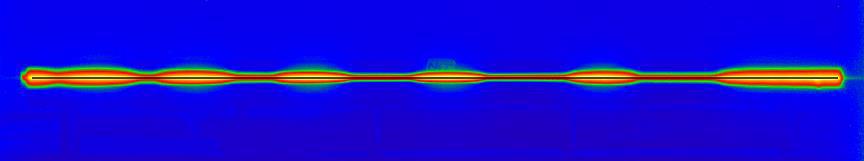

From a photometric point of view, these guides’ ability to conduct light makes it possible to obtain high luminances on large luminous surfaces. The luminance uniformity obtained is also excellent, with values above 80%.

However, the design of the optical systems is crucial and requires particular expertise to obtain such results at an acceptable cost.

Only a suitable combination of the correct LEDs, their operating points, materials, and surface treatments in a suitable architecture will make it possible to achieve the expected quality.

PISÉO has the skills and tools to reliably design, simulate, model, optimize, and characterize lighting systems using light guides, as well as any other system using photonic technologies.

For this, we rely on:

• the expertise of our engineers (Optics, Mechatronic Systems, Materials),

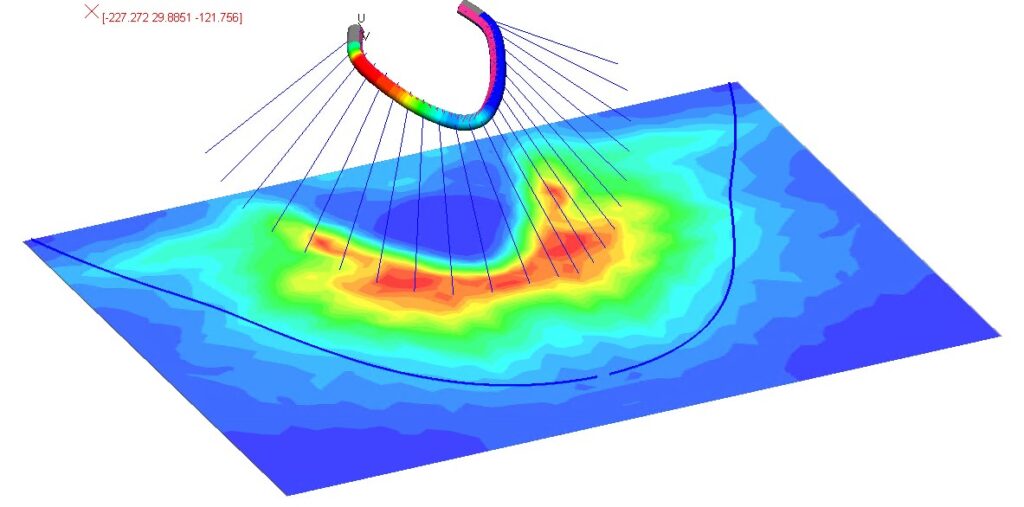

• our optical design and simulation tools, such as the ZEMAX Optic Studio and LightTools

• our proprietary algorithms

• our extensive materials database containing optical properties characterized in the laboratory

• our COFRAC-accredited characterization laboratory (scope available at www.cofrac.fr).

Our Westboro Photonics P1230U 12.3 MP video-luminancemetry camera and its lenses allow us, for example, to carry out 2-dimensional luminance measurements quickly and precisely. The luminance level and uniformity of any luminous surface can be characterized.

Light guides have several advantages: ease of integration, optimum performance with few LEDs leading to lower energy consumption than a multi-LED system, ease of production by machining or plastic injection, and aesthetic rendering, which are particularly appreciated by designers, manufacturers, and architects. However, a light guide obeys optical physical laws that must be respected to obtain all the advantages stated above.

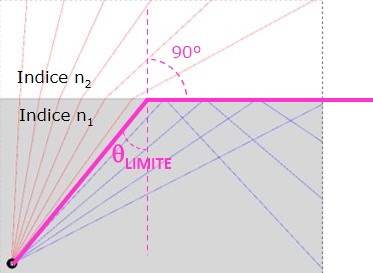

The first step – coupling the source with the guide – is crucial to avoid losses between the LED and the first input face. The characteristics of the LED and its operating point must, therefore, be judiciously chosen to obtain the maximum emitted flux. The guiding of light in matter is made possible by the phenomenon of total internal reflection. Depending on the guide material and its immersive environment, a limiting angle defines whether the ray will be reflected or transmitted.

If this condition is not adhered to, then the light ray escapes. This happens when the curvature is too pronounced or where there are surface defects (roughness, bubbles, etc.).

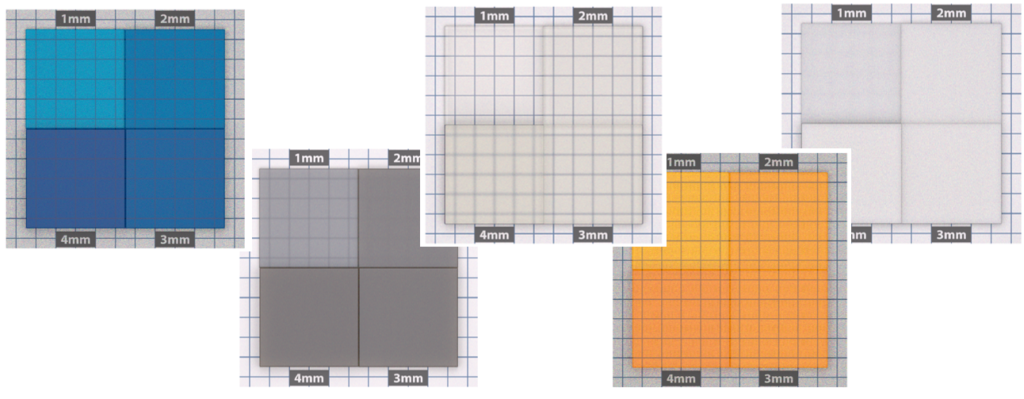

Conversely, to obtain a uniform light rendering along a guide, a well-designed diffusing surface that disrupts the light guidance properties is required. This makes it possible to extract the light in a pre-planned manner and obtain a uniform light rendering along a guide. For this purpose, we use the phenomenon of volume extraction (particles in the material) or surface extraction (surface texturing).

The choice of material is also critical. It must take into account the length of the guide, its geometry, and the mechanical constraints linked to the use of the product in which it is integrated (resistance to shocks, UV rays, etc.). Our extensive knowledge of the optical properties of materials, our independent database with relevant references, and our privileged relationships with many compounders allow us to quickly choose the correct materials, taking into account several criteria such as uniformity, luminance, transmittance according to length, volume diffusion, etc.)

Our optical design and simulation tools are able to integrate all the parameters mentioned above and thus accurately report the performance achievable by the optical solutions based on light guides developed by PISÉO engineers.

PISÉO experts have fully mastered these principles and are thus able to design the appropriate optical architectures and simulate their visual performance with their tools such as Lighttools or Zemax OpticStudio.

HMIs that incorporate a light guide often require the ability to display different colors. In this case, their coupling with colored LEDs, discrete or “packaged” and controlled by appropriate electronics and algorithms, is an excellent way to create a multitude of colors for these devices. However, achieving consistent color results on visible surfaces remains a challenge. In reality, only a specifically designed and carefully studied optical architecture, allowing efficient coupling of LED luminous flux and impeccable color mixing, is capable of producing a superior quality result.

PISÉO’s optical engineers benefit from extensive experience in the design of light guides for color mixing. They know how to take into account the mechanical and aesthetic constraints of the products and the manufacturability of the components to best meet your objectives.

Thanks to their network of trusted partners, PISÉO engineers are able to produce prototypes of light guides to validate their design. Like all optical components, to be sufficiently representative, these prototypes must be made with great care. This is why PISÉO offers to manage the entire process.

The light guides are then integrated into a system, allowing the pairing of the light source(s), generally LEDs wired onto printed circuits. The functional assembly is tested in the PISÉO laboratory. Precise measurements of luminous flux, illuminance light distribution, luminance, and colorimetric parameters can thus be carried out to check the prototype’s performance.

If you wish to integrate lighting systems based on efficient and qualitative light guides into your products, be like our many satisfied customers, and do not hesitate to trust the optical engineers at PISÉO.