Constant advances in imaging sensors and image processing techniques are revolutionizing the field of dental care.

ntegrating an intraoral scanner, combined with cutting-edge equipment, simplifies the manufacturing of prostheses and orthodontic devices, reduces delays, improves patient comfort and optimizes practitioner ergonomics.

Here you will discover how the advanced optical technologies integrated by PISÉO guarantee images of exceptional quality.

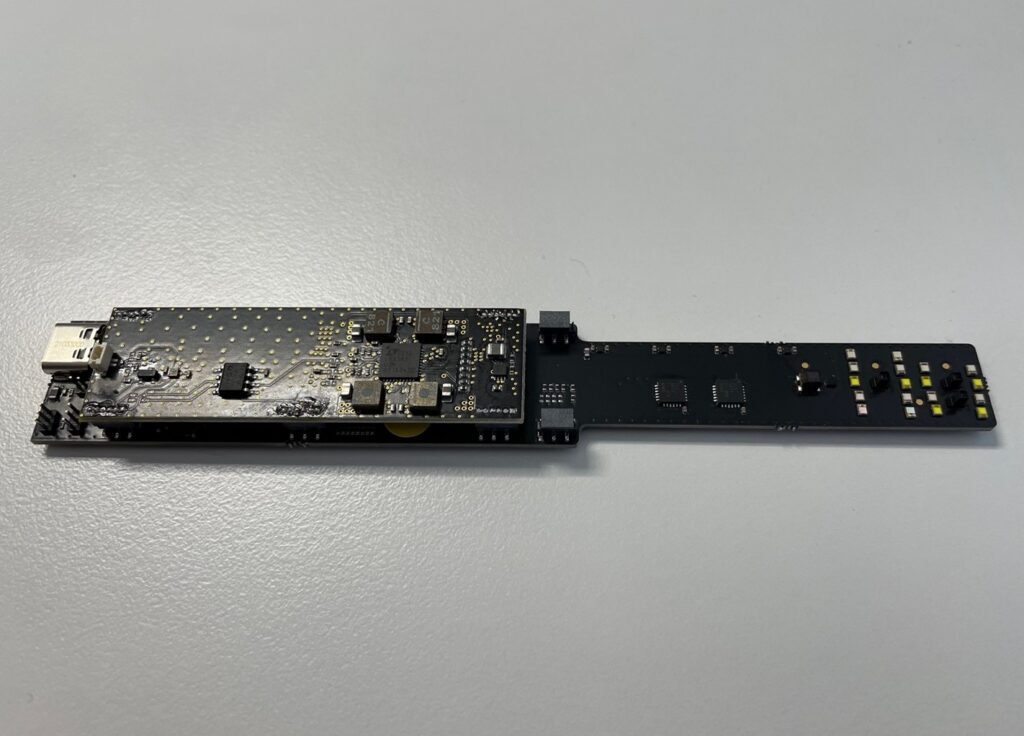

PISÉO has applied its expertise in optical imaging and lighting to the design of dental devices integrating high-resolution imaging sensors and specific LEDs. In collaboration with its partners, PISÉO has developed a fully integrated solution meeting the very high requirements of our client.

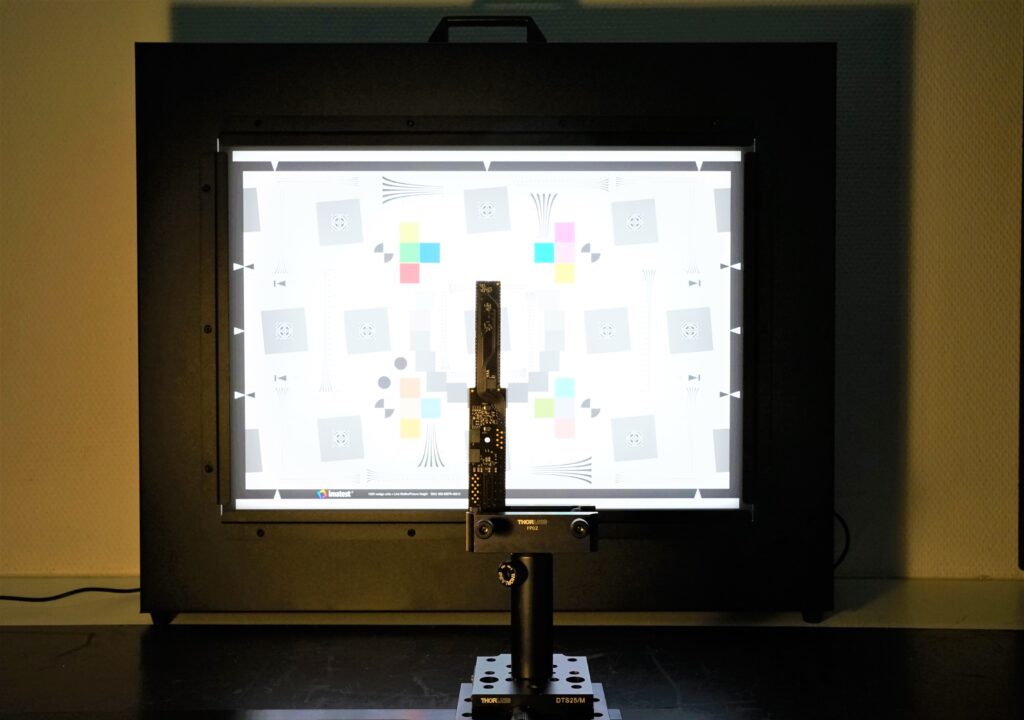

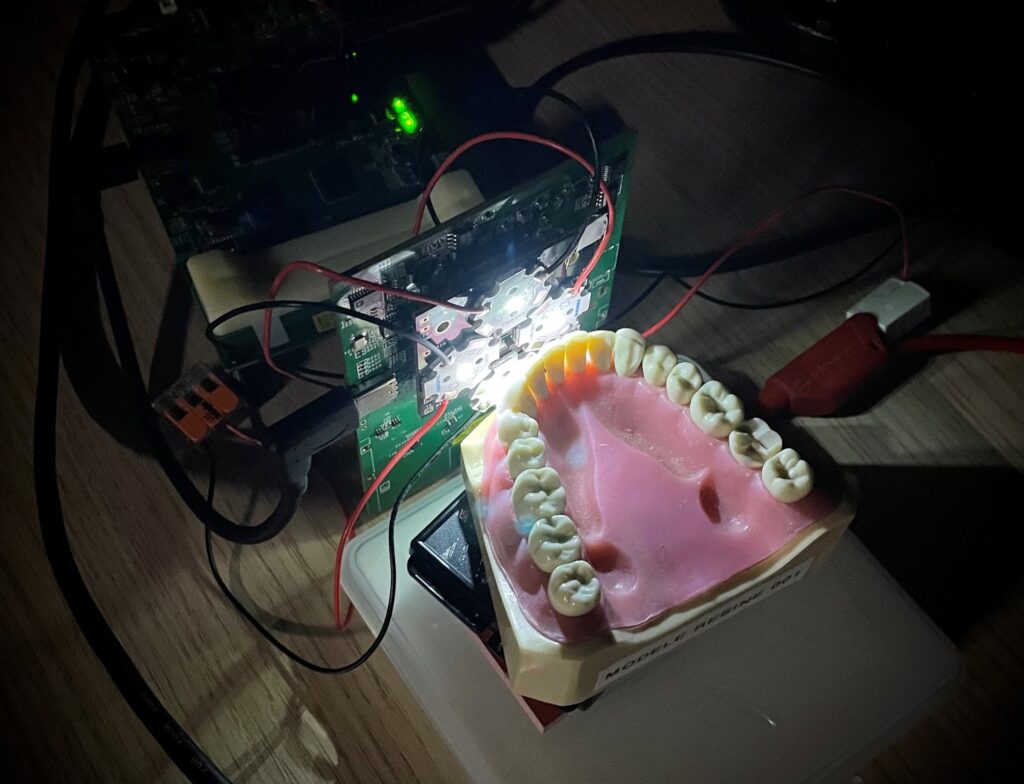

After an in-depth study of their optical and electrical characteristics, PISÉO experts chose and integrated very small, high-resolution imaging sensors. To this end, the PISÉO imaging laboratory evaluated the performance of these advanced sensors by carrying out measurements of MTF 50 on the object side, SNR and distortion. The tests also made it possible to assess the deformations generated by the rolling-sutter of the sensors. The results of these evaluations were taken into account to size and develop the LED lighting, as well as the electronics and on-board software. These characterizations associated with the development work ultimately made it possible to produce images of unrivaled quality for the client’s application.

In order to be able to produce optimal quality images in the oral environment, an efficient lighting system is required. For this project, PISÉO engineers, specialized in LED lighting, therefore designed specific lighting which provides, in all circumstances, all the illumination, colorimetry and contrasts necessary for the image sensor. In addition, to overcome the problems of image distortion linked to the use of rolling-shutter CMOS sensors, LED control electronics have been designed specifically for this product.

PISÉO’s structured innovation process made it possible to resolve the technical challenges of the project, with risk analyzes and action plans.

Calculations, optical simulations, and models and prototypes were carried out to test the functions of the scanner before industrialization, paying particular attention to performance, waterproofing, “manufacturability”, and compliance with CE medical regulations.

PISÉO ensures project management until mass production, taking into account regulatory aspects, quality, methods, logistics, and costing of the product. Collaboration with an assembly specialist guarantees optimal production of devices integrating optical and electronic functions.

The results of this project highlight the importance of a tailor-made approach in close collaboration with the Client. Opt for a personalized and efficient solution and trust the expertise of PISÉO and its valued partners for the development and manufacturing of your dental or medical devices.