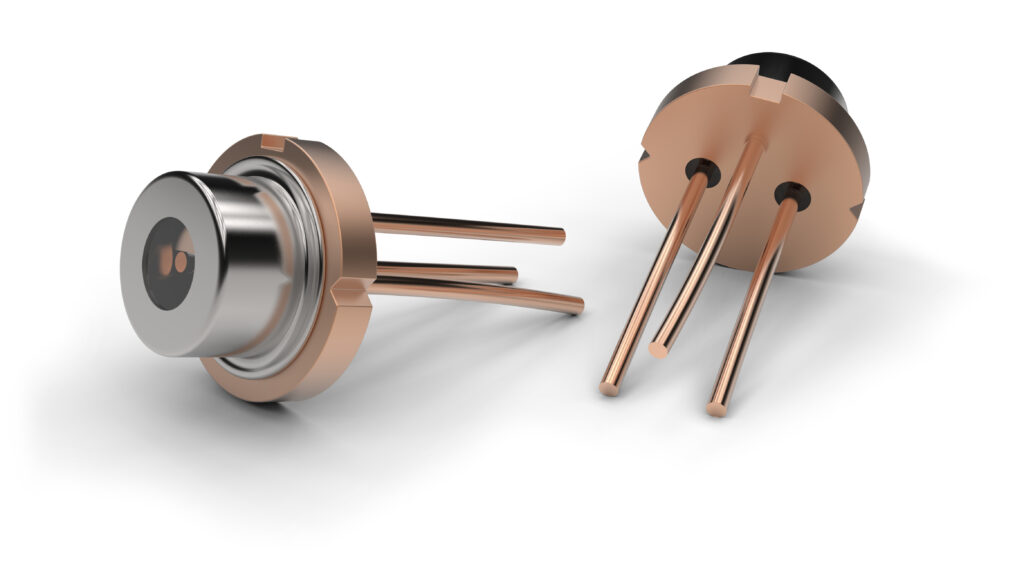

VCSEL is an acronym that stands for Vertical-Cavity Surface-Emitting Laser: a vertical-cavity laser diode that emits through the surface. After appearing in the late 1970s, VCSEL technology was first used in the 1990s in data transmission. However, since the early 2000s, this technology has been found in many everyday objects, such as laser printers and computer mice.

Many applications now use VCSELs: automotive radar, facial recognition … Widely used in the automotive industry and in smartphones, its manufacture and integration into systems require special skills, skills now mastered by PISÉO.

What are VCSELs?

VCSELs are semiconductor laser diodes that emit a light beam perpendicular to their surface. In physical terms, they are vertical stacks of semiconductor materials forming resonance cavities within which a laser-like light is generated as soon as a weak current passes through them.

Depending on the specific semiconductor materials used in the product, VCSELs can emit over a large portion of the electromagnetic spectrum, including ultraviolet, visible, and infrared. Most of its applications, however, are in ultraviolet and infrared.

What are the advantages of VCSELs over conventional LEDs?

? VCSELs can operate at high frequencies, hundreds of megahertz.

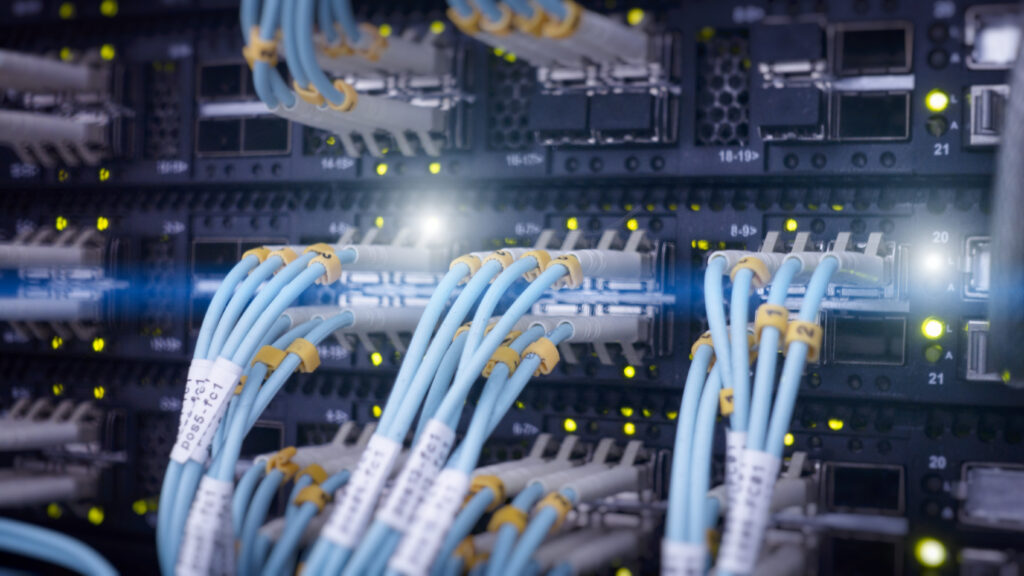

? They have a very narrow spectral band, making them more efficient in specific applications such as fiber optics.

? Their wavelengths are not very temperature-dependent.

? They are characterized by narrow light beams.

What are VCSELs used for today?

The VCSEL market is currently booming. According to Yole Développement (“VCSELs Technology and Market Trends 2021” report), a growth of 13.6% per year is forecasted until 2026. Currently, VCSELs are undergoing major technological changes, which will also create a new balance between manufacturers. Market size expected to reach $ 2.4 billion in 2023.

After approximately 40 years of technological development, VCSELs are now used in many applications, including consumer products.

Some examples :

In the general public

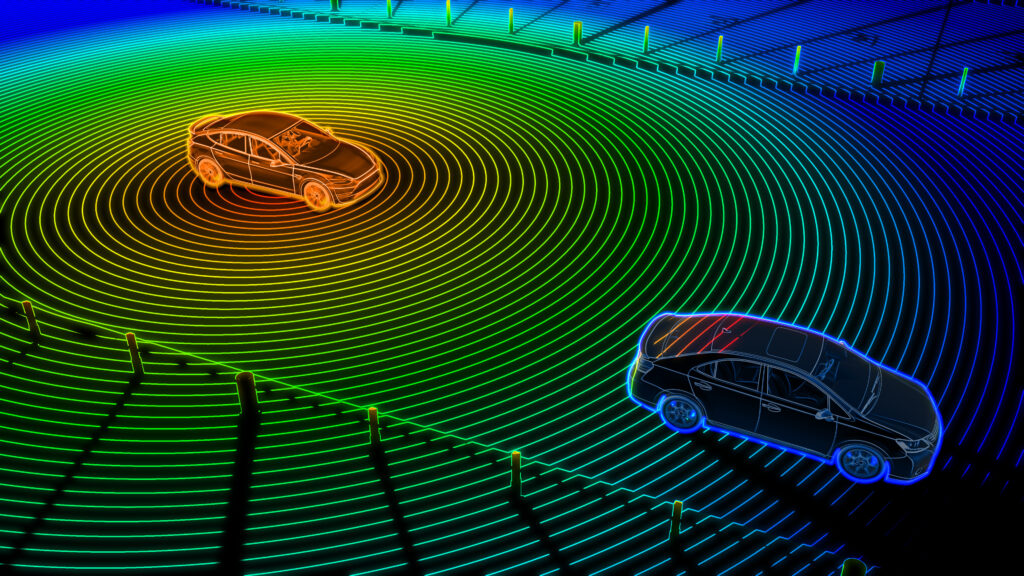

VCSELs are widely used in laser ranging. The distance to an object is calculated from the time between the light’s emission and its return from an object. This is used in, for example:

? the automotive sector: LIDAR, radar, driver monitoring, autonomous driving, etc.

? the smartphone industry: autofocus, facial recognition, etc.

In high-tech industry

Some examples :

? data transmission by optical fiber

? medical sector: neurostimulation and optical coherence tomography (OCT), blood flow measurement, ophthalmology, etc.

? industrial sector: data transmission system, industrial heating, security by video surveillance, etc.

PISEO ’s expertise

PISEO has been aware of the importance of this technology for many sectors and is constantly on the lookout for innovative illumination sources in the market. Its experts have inventoried and analyzed all the manufacturers of VCSELs. They have studied their qualities, their strengths, their weaknesses, and the advantages and disadvantages of each product and its manufacturer. This provides an unbiased benchmark that allows it to be a real source of practical information to its customers in defining the best component for each use case.

PISEO ‘s goal is to help its customers use VCSELs through product studies, development, integration of technology into products, design of systems that use them, characterization of optical performance, qualification, manufacturing monitoring, etc..

PISEO, and its team of 16 experts, imagines, designs, and manufactures systems using VCSELs for its customers and all types of applications. In particular, they invented, developed, produced, and qualified a system, unique in the world, for producing a very high-frequency light beam to perform useful tests for one of its customers, a world leader in microelectronics. Bare VCSELs are purchased in the United States and “packaged” by SERMA Microelectronics. The components are then mounted on a specific electronic card, designed by the company E.RE.C.A. It is assembled in a mechanical module designed and produced by the company E.F.S. Numerous temporal and photometric operational tests in a climatic chamber have been conducted within PISEO ’s laboratory in Vénissieux.

In this way, the module is qualified, its reliability assured, before delivery to the customer.

As a true conductor and architect of the system, PISEO supervised the three essential stages of the project: to specify, manufacture the subassemblies and assemble the product, and validate this innovative module created in a little serie.

An optical-photonics innovation center, PISEO has the internal resources to analyze light-matter interactions and then imagine, develop, build, and validate optimized industrial systems that integrate VCSEL.

In addition, its optical metrology test lab, partially accredited by COFRAC (scope available on www.cofrac.fr), allows the performance of these products to be tested according to various parameters.

Reports related to this article :

VCSELs – Technology and Market Trends 2021 (Yole Développement)

3D Imaging and Sensing – Technology and Market Trends 2021 (Yole Développement)

Apple iPad Pro LiDAR Module (System Plus Consulting)