> November 2021 : PISEO published an update of the report ” UV-C LEDs at the time of Covid-19″.

The health crisis due to the SARS-CoV-2 virus has generated unprecedented demand for the design and manufacture of disinfection systems using optical UV rays. LED manufacturers have seized this opportunity and we are currently seeing an explosion in the offer of UV-C LEDs.

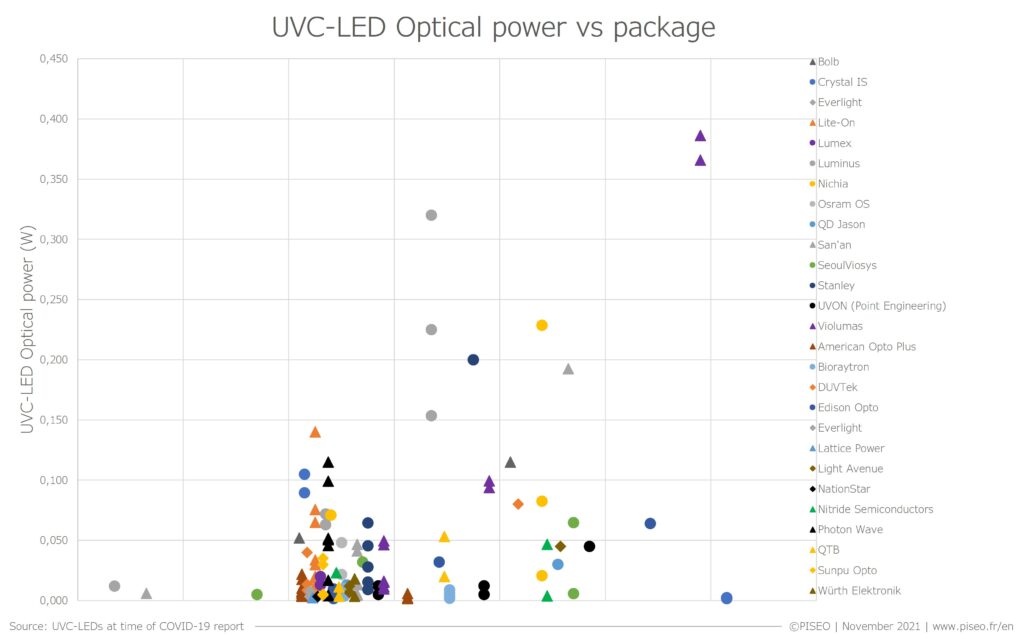

UV-C LED, an explosion of offers

The need for disinfection and the opportunity to use small light sources enabling more compact systems to be created, as well as the factor of new forms, have clearly generated renewed interest on the part of manufacturers of LEDs. Therefore, Piséo’s experts have been able to identify 15 new manufacturers of UV-C LEDs compared with the 2020 version of our report. The quantity of components currently on the market is unprecedented, and it is becoming difficult to compare them with one another as they are extremely diverse. Piséo’s experts have therefore analysed components available industrially as exhaustively and objectively as possible and compared them with one another. This approach means Piséo can offer the markets a complete overview of the current offer and provide system manufacturers with the key factors for making choices in full knowledge of the facts.

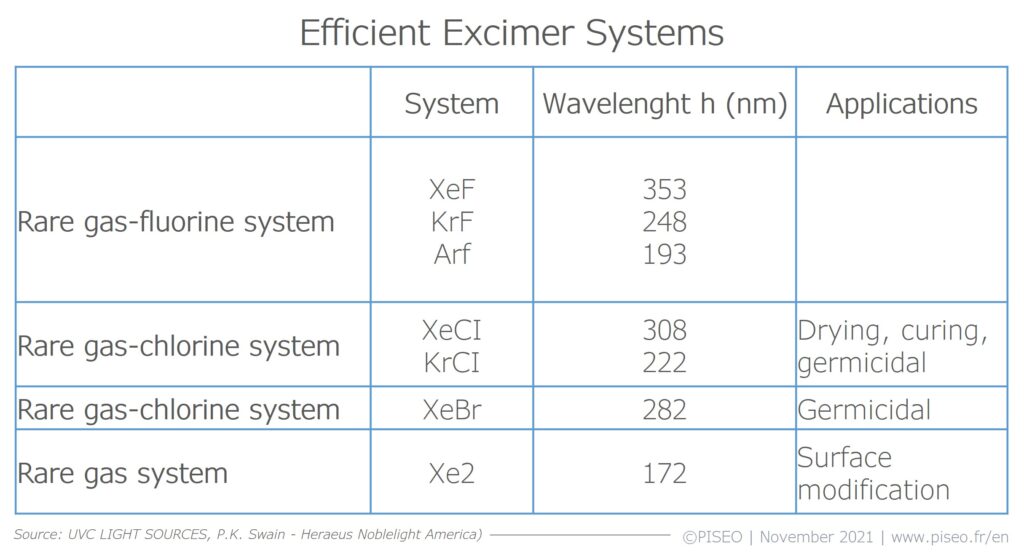

222nm disinfection, an ongoing debate

Although currently relatively scarce and expensive, several system manufacturers such as Signify, or Acuity Brands are taking a close interest in sources emitting a 222 nm wavelength due to the harmlessness of this optical radiation on the human body. Several products have already been placed on the market, and there are more to come which integrate excimer sources made by the company Ushio. Piséo’s specialists are therefore reviewing the state of medical research, the technology of sources emitting at 222 nm, the germicidal effect of this wavelength, the regulatory environment and the roadmaps produced.

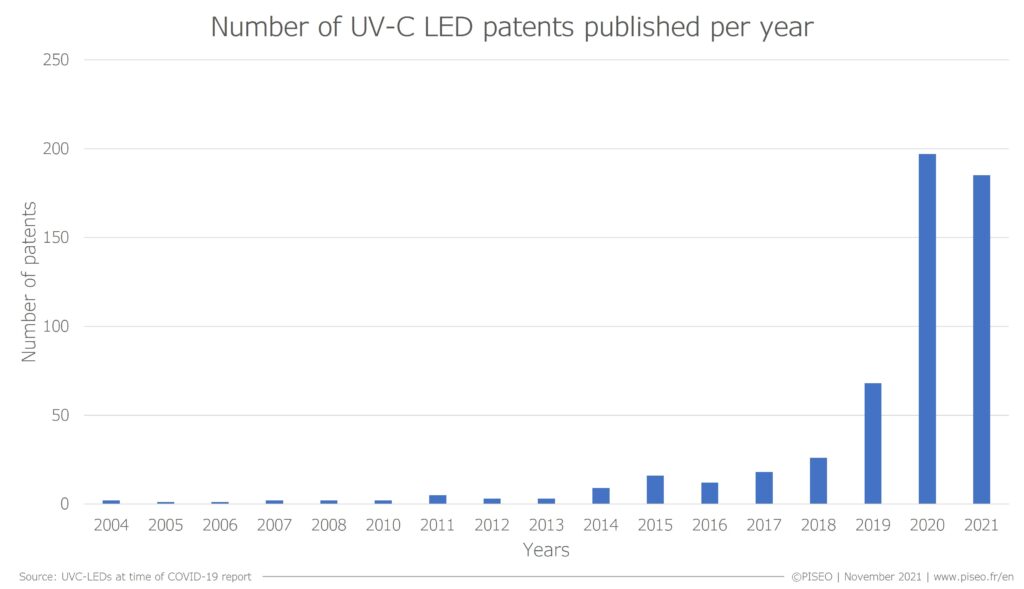

Covid-19, an outburst of patents in the UV-C Leds ecosystems

The number of patents filed in the last two years in the area of UV-C LEDs has exploded, thereby demonstrating the dynamism of research in this area. Apart from general trends, in this report we present the patents of 4 LED manufacturers whose content seems particularly relevant to us in view of the main challenges of the rollout of this technology: intrinsic efficacy and cost.

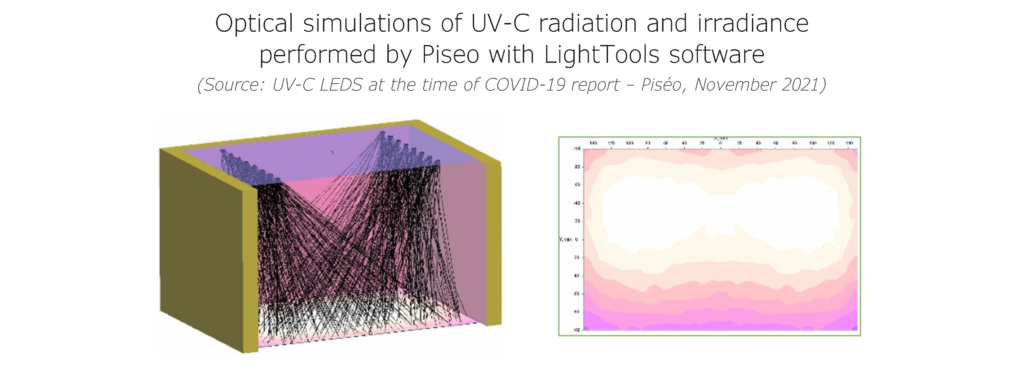

Optical design, the key to germicidal efficacy and safety

The still relatively weak performance of UV-C LEDs makes it necessary to take the optical-electrical parameters of these components into account in order to get the best out of them and thus guarantee disinfection through the design of the system. This is also true to ensure the longevity of the LEDs and prevent the photobiological risks to which users could be exposed. The report thus presents the principles to be implemented to ensure that the design of the systems is effective and safe.

Related reports

UV LEDs and UV Lamps – Market and Technology Trends 2021

PISEO has participated in the publication of other reports, notably with its partner YOLE DEVELOPPEMENT, the market research and strategy consulting company.

Media Contacts

Sandrine LEROY, Director, Public Relations

Marion BARRIER, Assistant, Public Relations